IT-7-IN-6082 Connectivity between imaging tools under controlled conditions: learning’s from 20 years experience with a variable cryo transfer system for the future

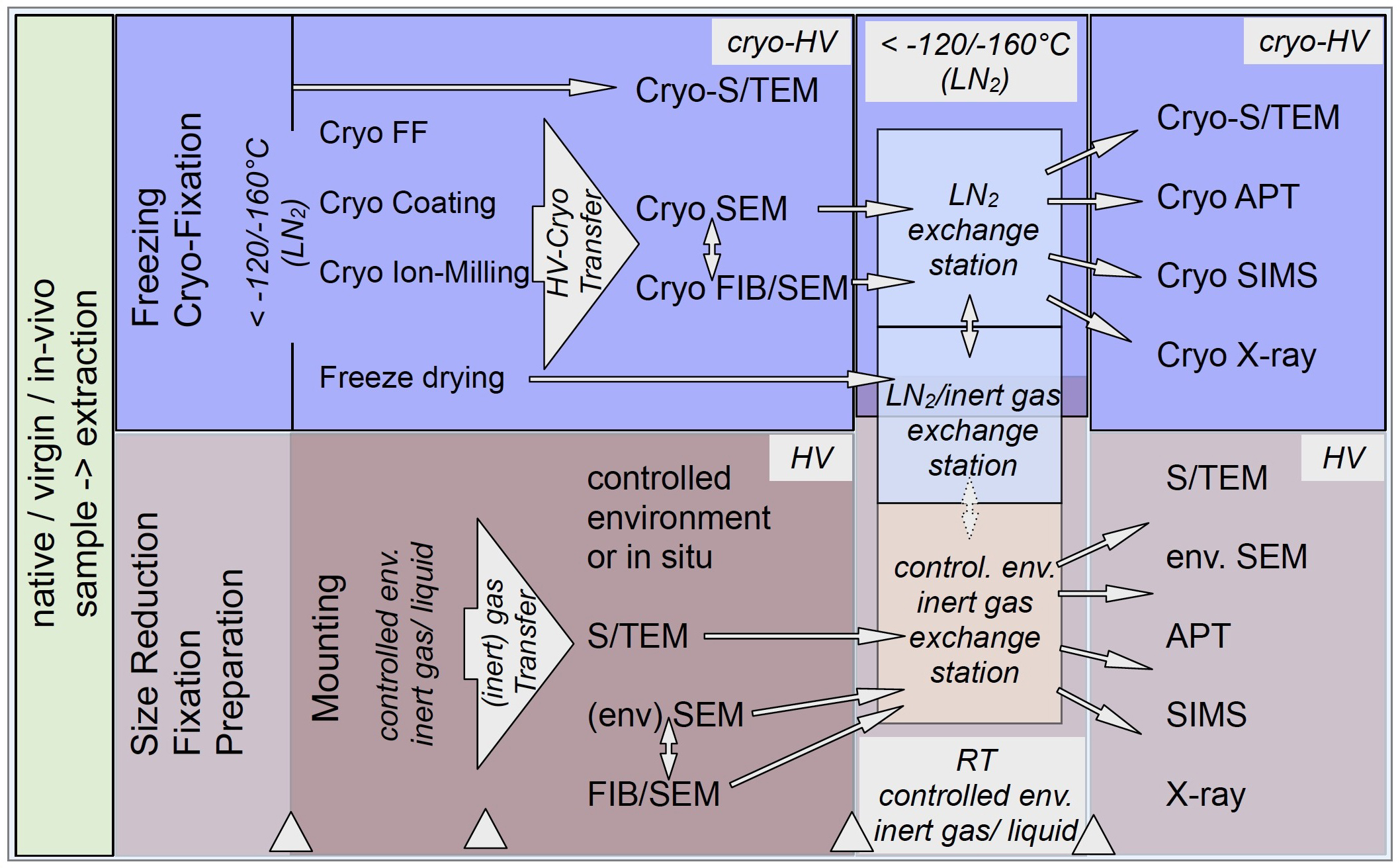

Sample preparation has become more crucial with modern microscopy and compositional analysis. The most obvious requirement, is that the specimen is reduced in size and exposed without relocating, changing or exchanging atoms or part of the sample, so to say with minimal or no alteration. Once prepared the transfer to the microscope is the last potential destructive step prior to the final analysis. To reduce such influences we therefore first established a controlled connection between a high vacuum cryo preparation device and a cryo-SEM (FEG-XL30 & cc-corrected LVSEM) in 1994 to avoid contamination of freshly prepared samples at cryogenic conditions and enhanced sample preservation and throughput for high resolution SEM work.

Soon later this system was brought to market by Bal-Tec under the name VCT, including a high resolution cryo-stage, and adapted to a large number of SEM’s, FIB/SEM, cryo-AFM, cryo-IonTof and others. Later it was also extended to ESEM’s for “inert-gas” or controlled environment sample handling.

Proofing that connectivity under “inert gas” or high vacuum between sample preparation devices and analysis devices combines higher sample quality with higher sample throughput without the risk of loosing samples due to contamination, change of structure by oxidation, amorphisation, cracking or simple loss of sample by remounting.

This kind of connectivity between single devices is well established in semi conductor industry in so-called fabrication plant or “FAB’s”-lines, where the sample (wafer) is handled between production and analytical stations such as LM, Spectrometer, EM, Auger- and SIMS instruments without any remounting and interference of an operator and mostly under high vacuum conditions for on-line quality and process control.

In structure research we often face the problem on non-periodic (non crystalline) samples that several independently and comparative studies do not merge into a common picture. Understanding materials heterogeneity at various order of scale very much depends on imaging and analysis the same area/region of interest (AOI/ROI) without the risk of changing the sample properties and configuration between the investigations. This not only helps to reduce multiple experiments but also allows to zoom-in on pin-point selected ROI by a correlative combination of analytical imaging investigations (EELS, X-ray, SIMS, APT).

If we want to maintain highest possible quality of our carefully prepared samples for multimodal analysis we need to establish versatile transfer devices between the different analytical tools. In addition we need to standardize sample handling and interfaces to be able to investigate “close to native” samples at different resolution and sensitivity scales ideally on the same ROI. This will not only help to save time and number of samples but improving the output of multimodal analysis.