IT-9-P-5973 In situ observation of reverse transformation in steels using EBSD measurement at elevated temperature

In the advanced high strength steels, the phase transformation from a high temperature phase of austenite with fcc structure to the low temperature one of ferrite with bcc structure, including of bainite or martensite phases must be controlled to get a suitable microstructure with good mechanical properties during the manufacturing process. Since there are several kinds of heating and cooling treatments in the steel product line, the nucleation sites and growth behavior in the forward and reverse phase transformation are important controlling factors, which are strongly affected by a local inhomogeneity such as precipitation, segregation, and crystal orientations.

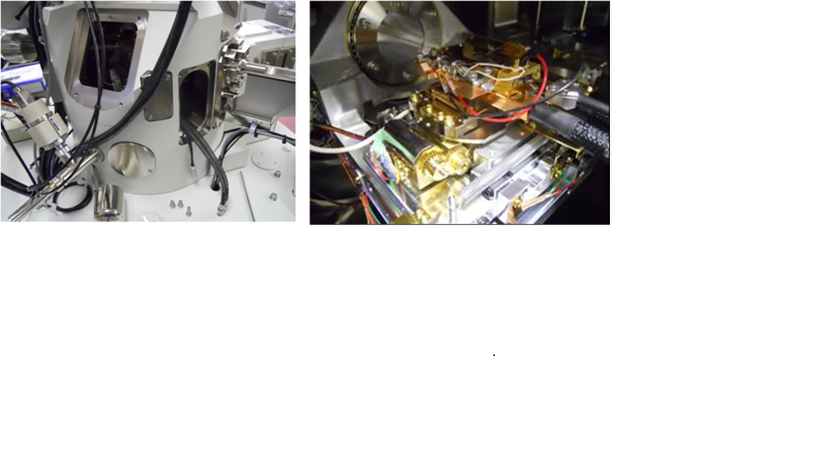

Using a field emission typed SEM equipped with the Electron Backscatter Diffraction (EBSD) detector, the resolution for the local crystal orientation area is improved up to about 20nm at room temperature. As a next step, the development of the EBSD measurement at elevated temperature is expected in order to carry out the in situ observation for the phase transformation, recrystallization and grain growth [1]. Since the observation temperature at a high temperature is depended by the capacity of the heating stage, we have applied a new heating stage developed by TSL solutions specified for the EBSD measurement. Figure 1 shows photographs of a part of SEM (JSM-7800), in which the heating stage has been installed. The sample size is 5.0 x 7.0 x 0.6 mm in dimensions. The thermocouples are mounted on both of a sample surface and the sample holder. The heating stage can be operated at tilting angles up to 70°and a radiation protected cover is fixed.

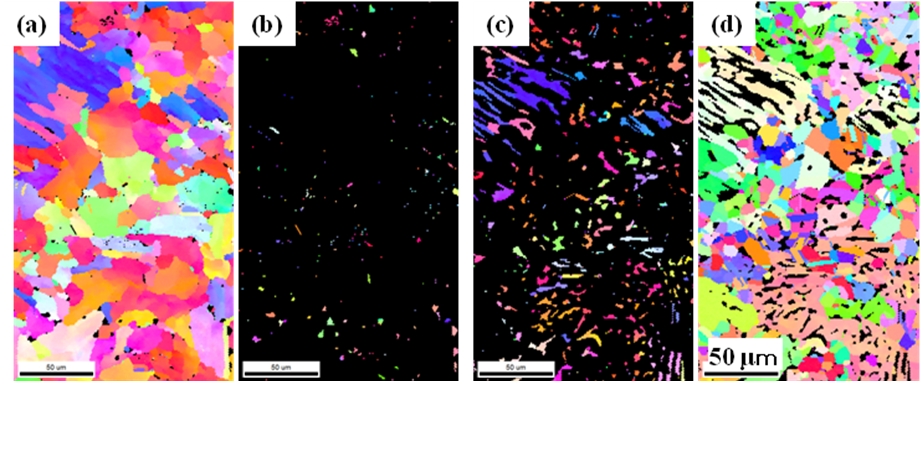

The reverse phase transformation from the ferrite to austenite phase in the bainitic steel has been investigated to make clear the austenite grain orientation memory effect [2]. Since the memory effect shows strong heating rate dependence and the heating temperature range, it is considered that the growth rate of retained austenite between the lath boundaries compete with the decomposition of cementite in the microstructure of the bainite phase. Figure 2 is one of examples showing the orientation imaging maps during the reverse transformation measured up to 1100℃. The in situ observation technique developed at elevated temperature with a stable drift control, it becomes possible to discuss the nucleation sites of the austenite and its orientation characteristics. The artifact arising from the vacuum experiment in SEM must be also discussed.

References

[1] S.Wright and M.M.Nowell ; Electron Backscatter Diffraction in Materials Science, A.J.Schwartz et al. (eds) , (2009) 329.

[2] T.Hara, N.Maruyama, Y.Shinohara, H.Asahi, G.Shigesato,M.Sugiyama, T.Koseki, ISIJ Int., 49(2009) 1792.

This work was supported by the New Energy and Industrial Technology Development Organization (NEDO) under the " Innovative Structural Materials Project (Future Pioneering Projects)".