IT-7-P-5752 Development of In-Situ Wet-Cell Electron Microscope Holder for Oxygen Nano-bubbles by Platinum

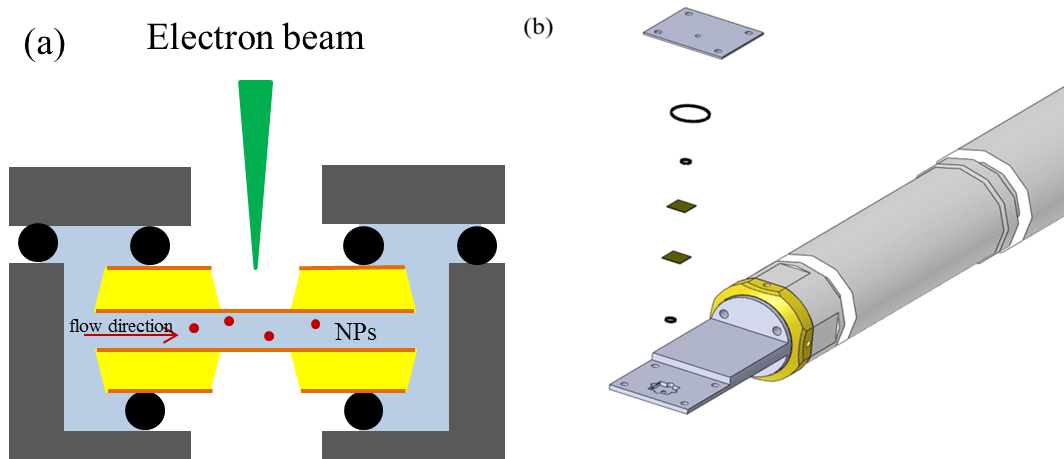

Recently, wet-cell electron microscopy provides a new method for investigating crucial scientific issues within liquid which beyond the conventional electron microscopy. The progress in electron microscopy pushes the capability of viewing as close as the original phenomena occur and thus may open new scientific windows in multi-field due to the spatial resolution in sub-nanometer as well as tens of millisecond time-resolved power. Much more researches has been published and included various field such as electrochemistry [1], catalyst material [2, 3], and biophysics [4]. Heimei et al firstly visualize growth dynamics of Platinum nanocrystal with nanometer resolution in wet cell TEM [2]. The above discoveries provide the key to understanding toward whole mechanism for synthesizing more efficient catalyst materials. In this research, owing to the significance of catalyst, we put more focus on investigating catalytic process of Platinum. For this purpose and to approach real case, we built up the platform with function of liquid circulation to fit with currently TEM (JEOL, JEM-2010 LaB6 equipped with Gatan multi-scan CCD) observation respectively, that is in-situ wet-cell electron microscope holder. The wet-cell chip is made by micro electro mechanical systems (MEMS) process and the observing window is 50nm Si3N4 [5, 6].

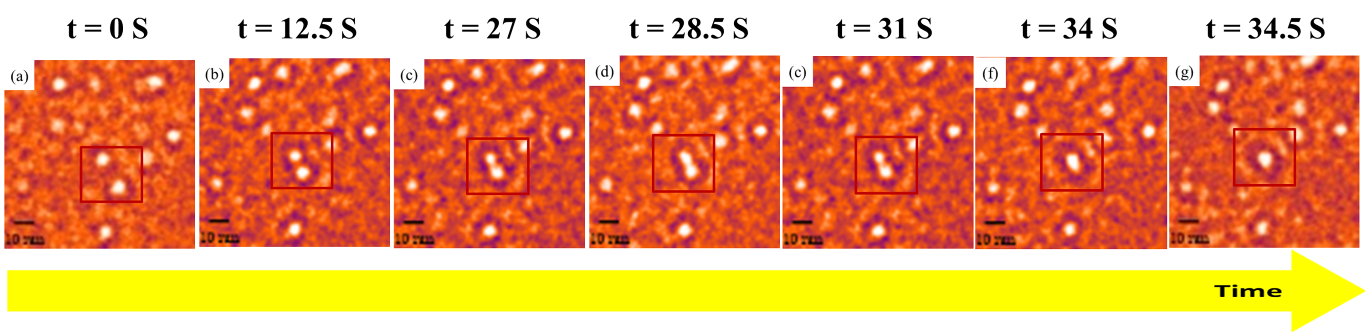

For TEM observation, the platinum nanoparticles was carried by multi-wall carbon nanotube was dropped onto wet-cell chip with electron transparent Si3N4 membrane then sealing was completed by a set of o-rings. The solution contains 0.08wt% of H2O2 have been transported into the observation area by syringe pump; additionally, the flow rate was accurately controlled below 0.15 mL/hr that is the key to preventing membranes broken. The bubble formation is due to the well-known equation: 2H2O2→ 2H2O+O2. Platinum serves as catalyst to promote hydrogen peroxide decomposed into water and oxygen, which contribute to the source of bubble generation.

References:

[1] M. J. Williamson, R. M. Tromp, P. M. Vereecken, R. Hull and F. M. Ross, Nature Materials 2 (2003), p. 532.

[2] H. Zheng, R. K. Smith, Y. W. Jun, C. Kisielowski, U. Dahmen and A. P. Alivisatos, Science 324 (2009), p. 1309.

[3] J. M. Yuk, J. Park, P. Ercius, K. Kim, D. J. Hellebusch, M. F. Crommie, J. Y. Lee, A. Zettle and A. P. Alivisatos, Science 336 (2012), p. 61.

[4] M. J. Dukes, D. B. Peckys and N. D. Jonge, ACS Nano 4 (2010), p. 4110.

[5] T. W. Huang, S. Y. Liu, Y. J. Chuang, H. Y. Hsieh, C. Y. Tsai, Y. T. Huang, U. Mirsaidov, P. Matsudaira, F. G. Tseng, C. S. Chang, and F. R. Chen, Lab chip 12 (2012), p. 340

[6] T. W. Huang, S. Y. Liu, Y. J. Chuang, H. Y. Hsieh, C. Y. Tsai, W. J. Wu, C. T. Tsai, Utkur Mirsaidov, P. Matsudaira, F. G. Tseng and F. R. Chen, Soft Matter 9 (2013), p.8854

This work was supported by National Science Council (NSC102-2321-B-007-007 and NSC 102-2120-M-007-006-CC1).