IT-7-P-3408 In situ TEM deformation of a bulk metallic glass with a K2-IS detector

Bulk metallic glasses are an exciting new class of materials due to their unique mechanical properties, such as high strength and good wear resistance. However, potential applications are hindered by their low ductility caused by the formation of shear bands leading to catastrophic failure [1]. The origin of these shear bands remains unknown. In order to investigate the structural mechanisms of shear band formation, in-situ deformation was carried out inside a TEM using a Hysitron Picoindenter and a Gatan K2 high speed direct electron detector. Samples were made from a bulk CuZrAlAg rod produced by vacuum casting.

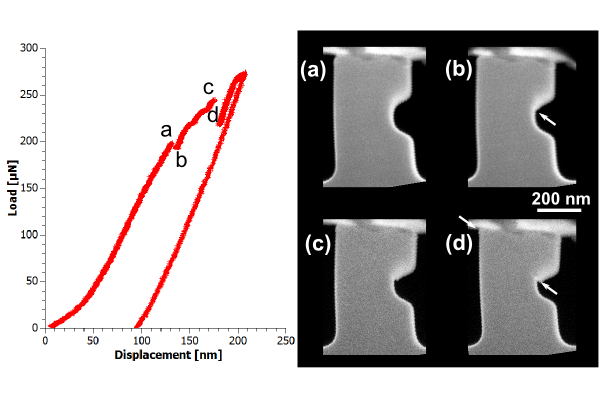

During the compression of nanopillars slipping events were observed but since the bands were not necessarily in projection they were difficult to analyze. To overcome this problem we used notched pillars to localize the deformation. Fig. 1 shows the results of a compression test carried out in dark-field mode. The video was recorded using a Gatan K2-IS direct detection camera at a frame rate of 400 f/s. The load displacement curve shows a long elastic regime followed by a sudden load drop. Two images were extracted, one right before and one right after the load drop (indicated with a and b, respectively). The images show the formation of a shear band as concluded from the shear offset that is indicated in (b). During further loading multiple small load drops can be observed followed by a larger loaddrop. The images taken before and after the large loaddrop (c and d) reveal that the load drop is caused by an abrupt slip event. The same shear band is reactivated (the trace of the shear band is indicated in (d)). Due to the fast frame rate of the camera it is possible to conclude that the time for the slip event was less than 2.5ms. The results indicate that after the initial formation of a shear band the pillar slips along this shear band in a stick-slip motion.

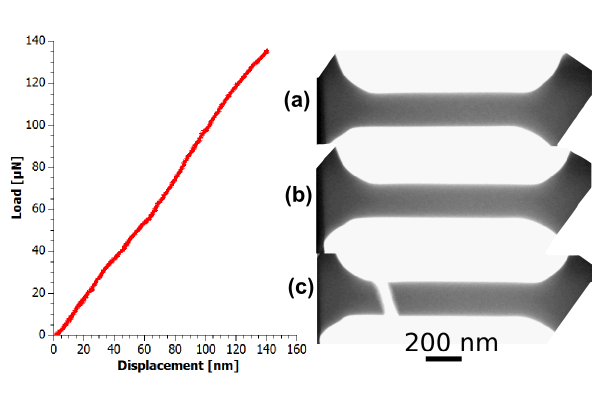

In addition to compression tests, tension tests of the metallic glass were carried out. Tension samples were made by transferring the sample to a Hysitron Push-to-Pull Device that allows using the Picoindenter as in-situ tensile apparatus [2]. Fig. 2 shows the result from an in-situ tensile test acquired in bright-field mode. The corresponding load displacement curve shows elastic deformation followed by an abrupt fracture with no indication of plasticity. In addition, digital image correlation from decorated samples was used to examine the origin of shear band formation. These results will be described in terms of the relationship between local shear transformation zones and eventual shear band formation and propagation.

[1] A.L. Greer. Science 267 (1995) 1947.

[2] H. Guo, et al. Nano Lett. 11 (2011) 3207.

The authors acknowledge support by the Austrian Science Fund (FWF):[I1309, P22440, J3397] and by the National Center for Electron Microscopy, Lawrence Berkeley Lab, supported by the U.S. Dept. of Energy under Contract # DE-AC02-05CH11231.