IT-7-P-2824 Understanding mechanisms of assisted sintering through dedicated in situ TEM experiments

Sintering describes the densification of powder agglomerates through elimination of “empty space” between individual particles. [1] The application of electrical fields, currents and/or pressure in addition to heating can enable the accelerated consolidation of materials. While electric field assisted sintering, which includes spark plasma sintering and flash sintering, is already employed for the synthesis of a wide variety of microstructures with unique macroscopic properties, a fundamental understanding of the atomic-scale mechanisms that lead to enhanced densification is mostly absent from the literature. In this presentation, recent in situ transmission electron microscopy experiments will be reported that were designed to investigate specific densification mechanisms, including surface cleaning effects, i.e., dielectric breakdown of insulating surface oxides [2], mechanical properties of individual ceramic powder agglomerates [3], and electric field effects on the densification of yttrium-stabilized zirconia.

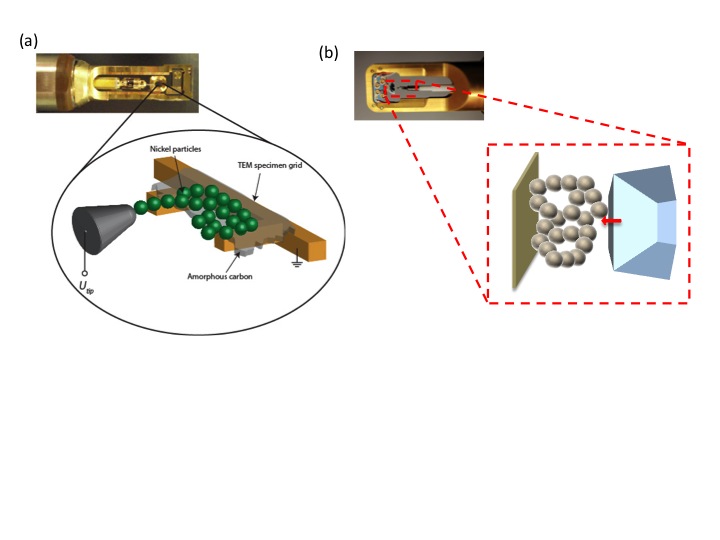

To quantitatively evaluate densification behavior we have developed an image processing tool to obtain three-dimensional densification curves from powder agglomerates. A variety of in situ TEM experiments was used to electrically contact individual nanoparticles (Figure 1a), apply mechanical pressure to particle agglomerates (Figure 1b), or expose particle agglomerates to electrical fields in non-contact mode. The results reveal that dielectric breakdown of insulating surface oxides on nanometric metal particles causes retardation of densification, while the morphology of ceramic powder agglomerates can limit densification through stabilization of pores. The application of electrical fields during in situ sintering experiments in the TEM reveals that the field strength in the absence of current has an appreciable influence on the densification behavior of Y-stabilized ZrO2. Moreover, the application of electrical fields promotes the formation of coincident site lattice grain boundaries and, hence, can accelerate grain growth in ceramic microstructures.

References

[1] Castro R, van Benthem K. Sintering: Mechanisms of Convention Nanodensification and Field Assisted Processes. Heidelberg: Springer, 2013.

[2] Bonifacio C, Holland TB, van Benthem K. Evidence of surface cleaning during electric field assisted sintering. Scripta materialia 2013;69:769.

[3] Rufner J, Holland TB, Castro R, van Benthem K. Mechanical properties of individual MgAl2O4 agglomerates and their effects on densification. Acta mater. 2014;69:187.

This work was supported by the University of California Laboratory Fee Program (12-LR-238313) and the Army Research Office (program manager: Dr. S. Mathaudu) under grant W911nf-12-1-0491-0.