IT-10-P-2637 Combined 3D characterization of porous zeolites by STEM and FIB tomography

Conventional transmission electron microscopy (TEM) techniques are usually limited to acquire information of specimen in two dimensions. In many cases, a three-dimensional (3D) characterization is required, as is the case for porous materials used in catalysis, for which a detailed knowledge of the 3D-morphology, size distribution and interconnectivity of the pores is crucial.

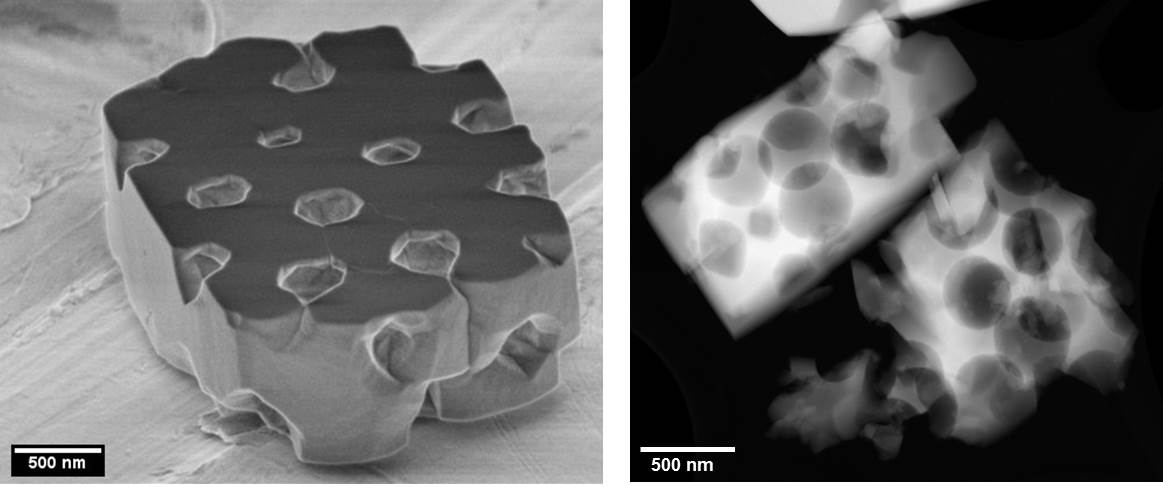

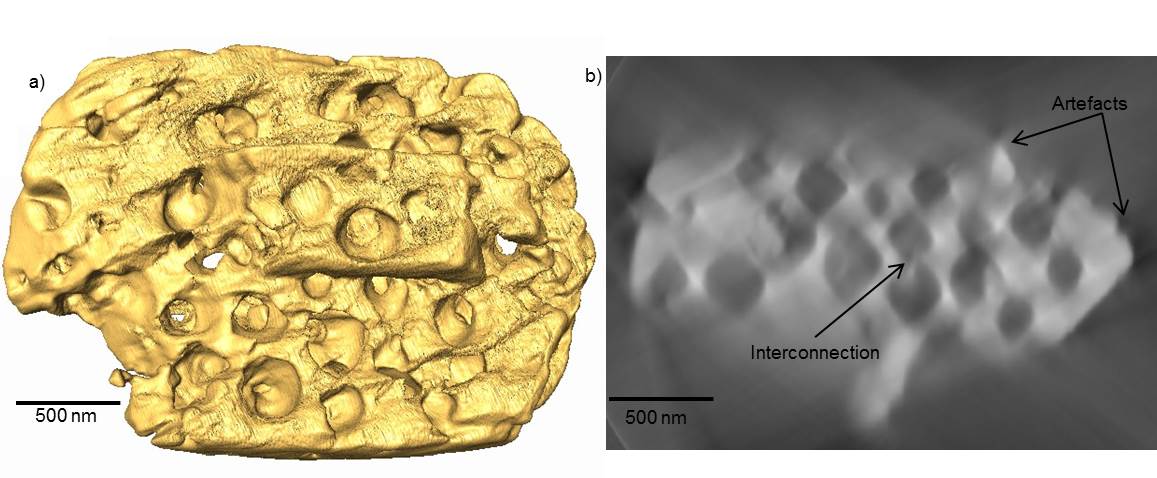

In this work we compare the 3D characterization of micro- and macroporous zeolite particles used as catalyst support (Fig. 1) with the aim of obtaining a detailed analysis of its porous structure by two different and complementary techniques, namely electron tomography (ET) based on annular dark-field (ADF) scanning TEM (STEM) and focused ion beam (FIB) tomography. The size of the particles is in the range of several micrometres, so both techniques are applicable with their specific advantages and disadvantages. ADF-STEM ET has been performed in a FEI Titan3 80-300 microscope at 200 kV, with a spatial resolution of 2.1 nm and a convergence semi-angle of 5 mrad for an increased depth of focus. Tilt series have been acquired in a tilt range from -72° to 72° (1.5° tilt increments). For the 3D reconstruction, the simultaneous iterative reconstruction technique (SIRT) algorithm has been applied with 50 iterations. ADF-STEM ET has revealed a porous structure (Fig. 2a) with mostly interconnected pores. However, due to the missing wedge, artefacts in the reconstruction can be observed due to the lack of information for the highest tilt angles (Fig. 2b).

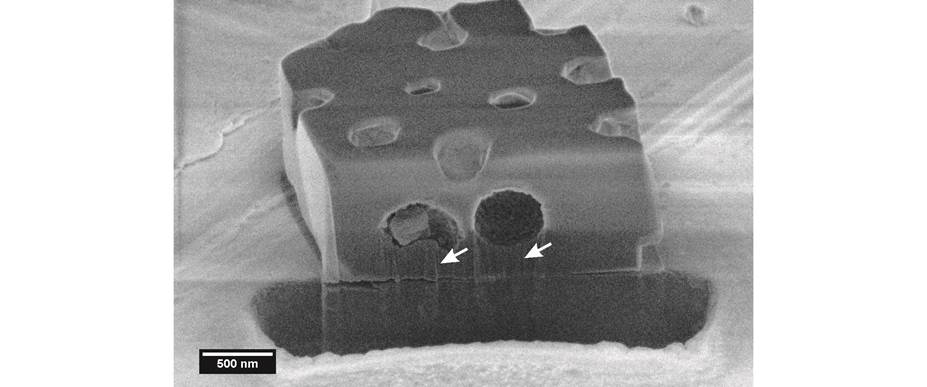

In order to reconstruct larger volumes FIB tomography is a well suited alternative. In this case, a FEI Helios NanoLab 660 Dual Beam FIB is used to perform the sequential milling and imaging with a depth resolution of 20 nm by using a milling voltage of 5 kV and beam currents in the range of 10 - 40 pA. Fig. 3 exemplarily shows the SEM image of one slice recorded during a FIB tomography series. The pores are nicely resolved. However, in this case the well-known curtaining effect leads to artificial striations in the shadow of pores.

The combination of both tomography techniques is well suited for a more complete 3D characterization of such medium-sized structures. Further work is focusing on the combined application of 360° ET (full tilt-angle range) and (subsequent) FIB tomography to one and the same particle and a detailed comparison of the reconstructed volumes. The application of 360° ET prevents missing wedge artefacts and, therefore, improves the quality of the reconstruction.

Financial support from the German Research Foundation through the Priority Program 1570 and the Cluster of Excellence EXC 315 “Engineering of Advanced Materials”.