IT-10-P-2420 Tilt-less Electron Tomography

Accurate three-dimensional (3D) knowledge of dislocation structures is more and more vital for the understanding of complex deformation mechanisms at the nanometer scale. In this respect, tomography in transmission electron microscopy developed in the area as a fruitful technique, but is demanding and sometimes inapplicable, as it requires the acquisition of multiple images within a large tilt range [1-4]. The major challenge to electron microscopists now is the development of efficient techniques to overcome these limitations and thus facilitate 3D reconstructions.

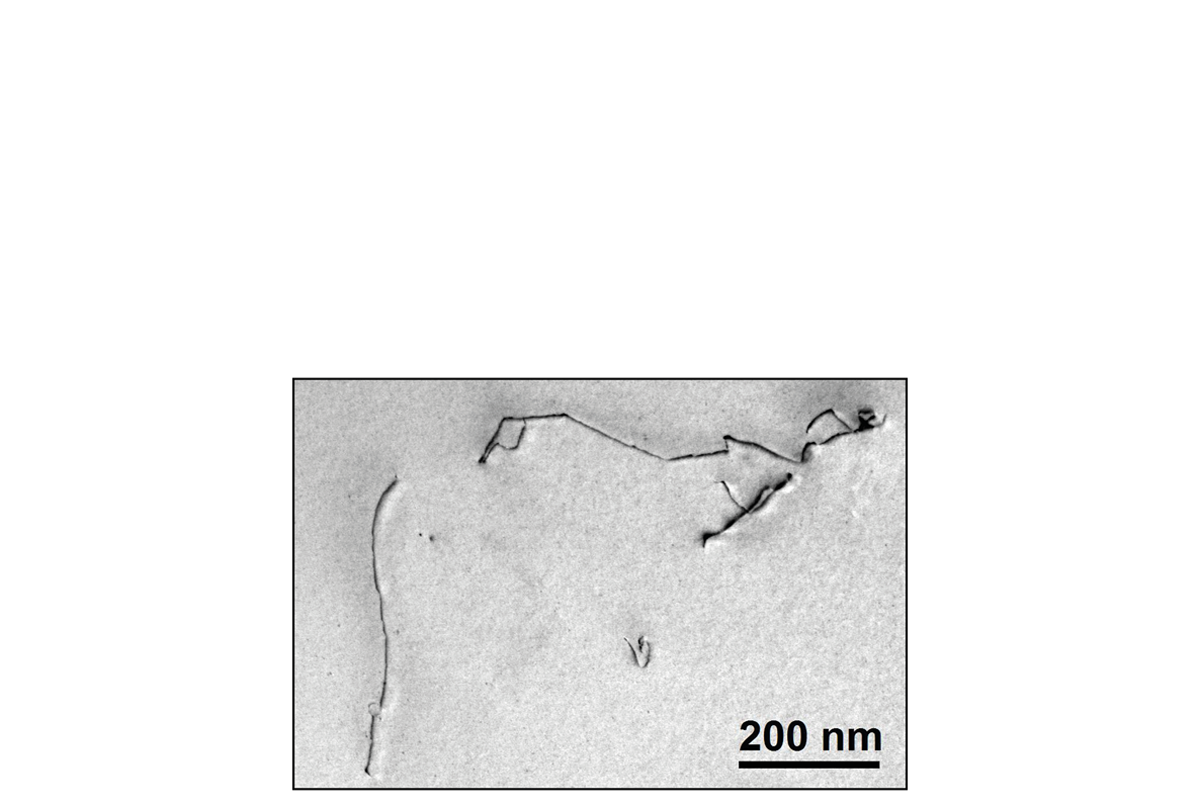

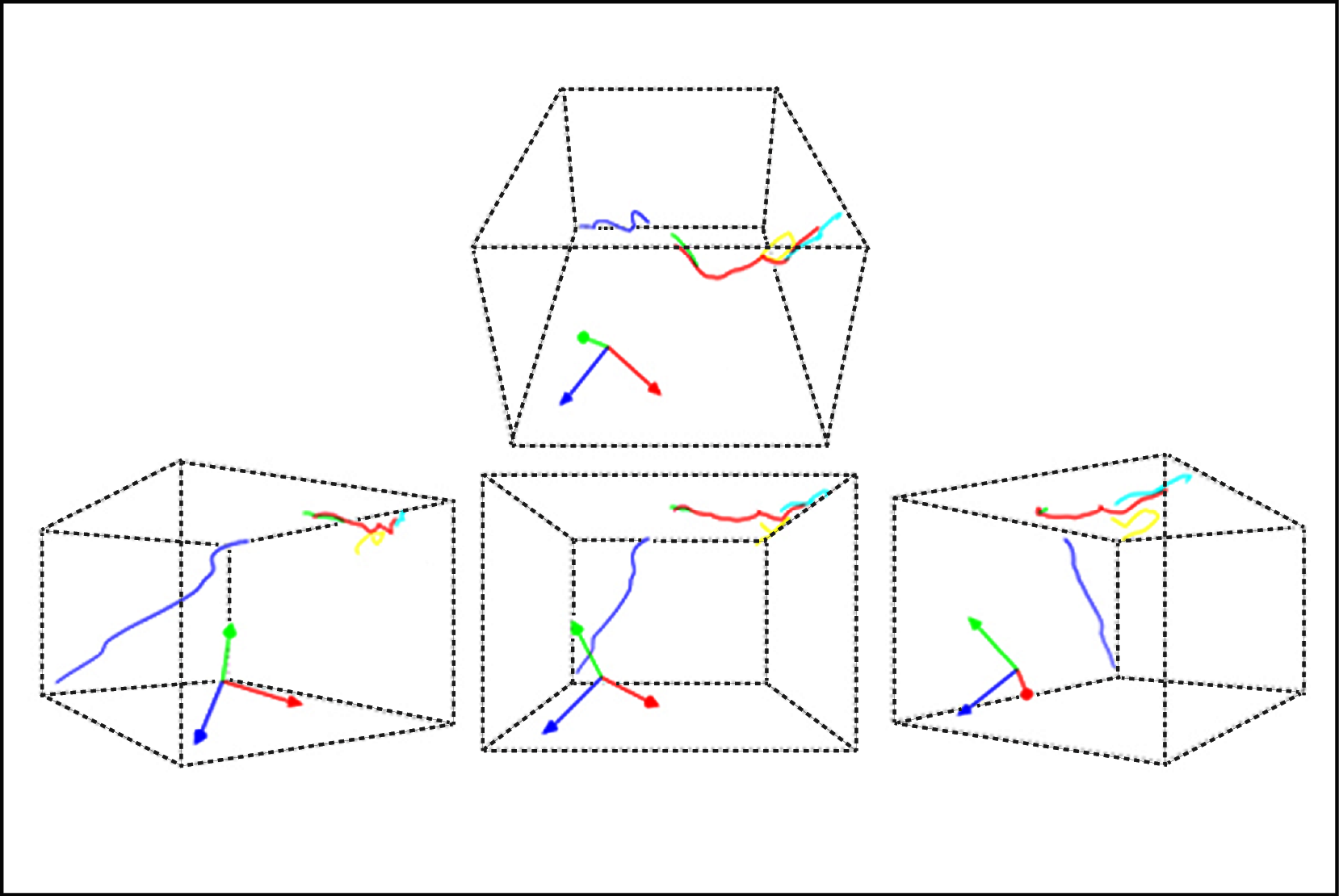

We have developed an efficient method that provides a highly reliable insight into the 3D reconstruction of dislocations, in which both image acquisition and reconstruction are addressed. This technique makes use of the convergent electron beam in scanning transmission electron microscopy (STEM) and provides from a single viewing direction a stereoscopic pair of micrographs. Our newly reconstruction algorithm allows us to derive the true structure of dislocations in three dimensions on the sole basis of the acquired stereoscopic micrographs. The reconstruction algorithm firstly extracts, from the STEM stereo images, the dislocation lines using state of the art curvilinear structures detection algorithm. These 2D representations of dislocations are then automatically matched between images. Finally, the algorithm, given the projection parameter and the corresponding virtual tilt angle of each image, can then reconstruct the 3D structure of the dislocations. The method is successfully demonstrated on the 3D visualization of dislocation arrangements in a Fe-10Cr model alloy.

With a proper input of the crystallographic axes of the specimen in the algorithm, the visualization tool allows determining the habit planes of the curves in the dislocation lines. The missing wedge effects are reduced in the 3D structure reconstructed via this algorithm, and “replaced” by a small uncertainty along the Z-axis, that thanks to purposely-designed smoothing techniques applied in the algorithm, can be kept in the range of few pixels.

In summary, this efficient and straightforward technique will markedly facilitate the 3D reconstruction and, if prior knowledge about the object can be ascertained, can be extended to a wide range of fields in which tilting associated problems, specimen thickness, and sensitivity to electron radiation are the limiting factors.

[1] P.A. Midgley, R.E. Dunin-Borkowski, Nature Materials 8 (2009) 271.

[2] J.S. Barnard, J. Sharp, J.R. Tong, P.A. Midgley, Science 313 (2006) 319.

[3] M. Tanaka, M. Honda, S. Hata, K. Higashida, Materials Transactions 49 (2008) 1953.

[4] M. Weyland, P.A. Midgley, Materials Today 7 (2004) 32.

Prof. P. Stadelmann, Dr. D. Alexander, and Q. Jeangros are gratefully acknowledged for stimulating discussions. This work was financially supported by Swiss National Science Foundation for scientific projects.