IT-7-P-2418 EBSD Measurements of the Twinning Process in an Mg-4wt%Li-Alloy with an in-situ Tensile / Compression Module in the SEM DSM 982

The combination of a tensile / compression module in a scanning electron microscope (SEM) enables the in-situ analysis of the microstructure modifications as a function of the applied load and strain direction. To analyze the microstructure in a SEM quantitatively, an electron backscattered diffraction (EBSD) measurement is the most promising tool. Unfortunately, the information depth of the EBSD signal is very small; therefore, it needs first to be clarified first if an EBSD-signal might be recorded from stressed specimen surfaces. This investigation is the purpose of this paper.

These measurements require a large specimen chamber with the possibility containing the module and a sample stage whose loading capacity is large enough for the module. Furthermore, for EBSD measurements it is essential that the EBSD-detector can be positioned as close to the sample as possible to optimize the data collection. Additionally, shadows of the module on the detector should be minimized. We used a tensile / compression module from Kammrath & Weiss in the "Narrow version" and a Zeiss SEM DSM 982 with Gemini optic. The used EBSD-detector is a Pegasus system from EDAX with a high speed CCD camera (Hikari). All technical difficulties with the integration of the module, the shadowing and the sample alignment are described in [1].

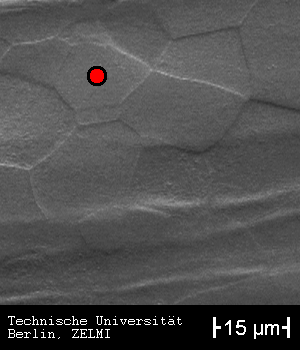

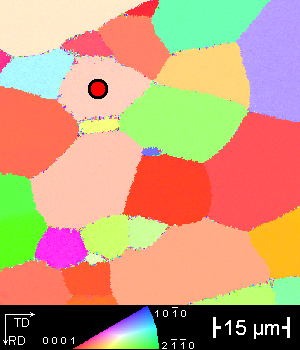

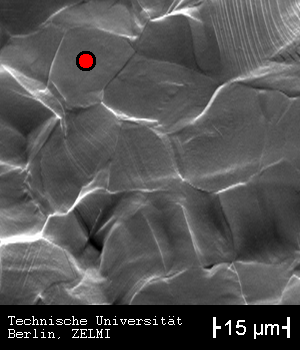

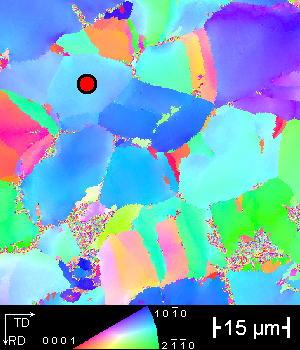

An Mg-4wt%Li-1wt%Al alloy was investigated whose misorientation relations should be determined. The deformation behavior of magnesium alloys is significantly influenced by the activation of mechanical twinning. Hence, twin nucleation and growth will be observed through characteristic reorientations during several load steps. Figure 1 and 2 show an EBSD-measurement of an Mg-4wt%Li alloy of an unloaded sample with the initial grain orientation. Figure 3 shows the surface of the same specimenposition after a compression of 14% in horizontal direction. The surface of the specimen became quite rough indicating a strongly strained surface. Nevertheless, it is still possible to record meaningful EBSD-maps (fig. 4). Only some areas close to grain boundaries are strongly deformed. In addition, the EBSD-map reveals that the grains have a preferred orientation after compression. The change of the orientation through twinning might be observed in subsequently recorded EBSD-maps during compression. In figure 4 several grains are still twinned while others are already completely sheared.

The presented results confirm that EBSD-measurements are still possible on strongly compressed specimens and that the complete twinning process during the increasing deformation might be observed and analysed in-situ.

[1] Microscopy Conference MC2013, Regensburg

The authors would like to thank Prof. Reimers for providing access to the tensile / compression module.