IT-1-P-2325 AC- Voltage Operated Schottky Electron Source

Introduction: Zr-O/W100 Schottky electron source has been widely used in electron beam instruments because of its favorable properties such as 1)vacuum technological tolerance at its operational condition, 2) rather long life time and high brightness. It is still required, however, that a vacuum must be better than 10 -8 Pa and stability of high voltage must be better than 10 -5 when DC high tension and electro-magnetic lens systems are used in the instrument. We tried to find promising materials. Among them, we selected BaZrO3 and SrZrO3 and tested their thermal field emission properties with both DC and AC high tension powers.

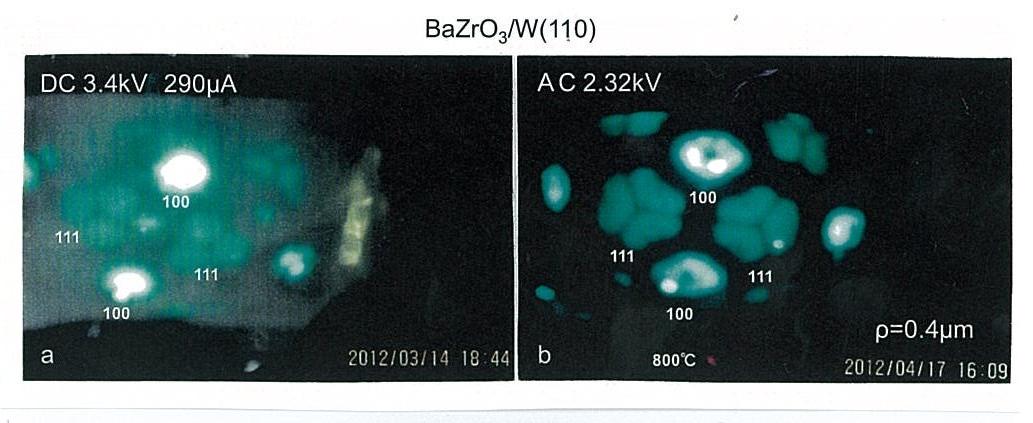

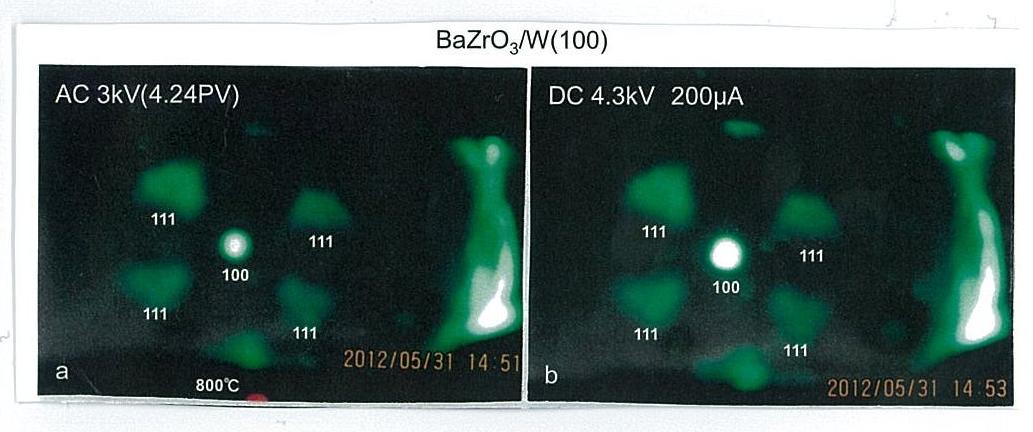

Results: Field emission tips of 110- and 100-oriented W wire were made by electrolytic method and powder of BrZrO3 or SrZrO3 was pasted near the apex as usual. Thermal field emission patterns obtained by DC and AC voltage are very similar and crystal facets are indexed very easily. Fig.1 and Fig2 show emission patterns of BaZrO3/W(110) and BaZr3(W100) obtained by AC and DC operation ,where optimal working temperature is 800 degree C. Similar results are obtained with SrZrO3(W)100 cathode but its optimal temperature is little higher than the case of BrZrO3.

As advantages of AC operation of present schottky electron source, followings are concluded:

1)Schottky shield is not necessary because of low working temperature of the emission materials.

2)Emission beams can be focused, deflected and stigmated by using electrostatic lens,deflector and stigmtor, respectively.

3)Work function of newly adopted materials here is so small that working temperature is fairly low (800-850 degreeC). Consequently ,energy spread of the beam will be narrow.

4) As commercial AC electric supply can be used without any rectifire or stabilizer, factor cost will be fairly reduced.

5)We think that the present Schottky electron source is the best selection for a generation of strong and small X-Ray source of projection X-ray microscope.

Fig. 1: Fig.1 |

Fig. 2: Fig.2 |