IT-13-O-2227 Temperature Evolution during FIB Processing of Soft Matter: From Fundamentals towards TEM Lamella Preparation

During the last decade focused ion beam (FIB) processing became a well-established technique for the site-specific preparation of ultrathin lamellas for transmission electron microscopy (TEM) but also for sub-surface 3D metrology and 3D prototyping on the nanoscale. Beside the undoubted advantages of straightforward implementation, FIB processing entails unwanted side effects, such as ion implantation, amorphization and partial high thermal stress [1]. While the former two are intrinsic properties and therefore invariable, local heating effects have been shown to depend strongly on the patterning strategy. The minimization of this technically induced heating is essential for low melting materials but requires deeper understanding of thermal effects during scanning.

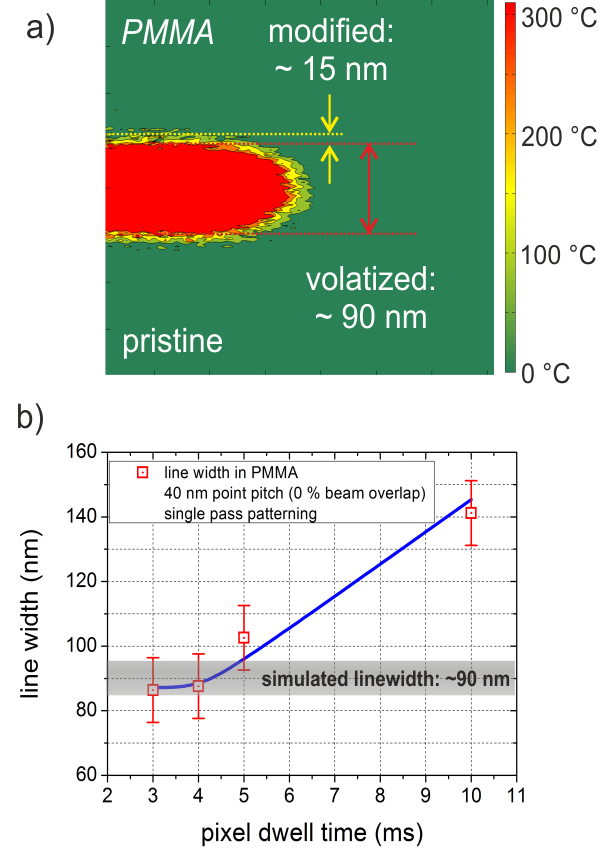

Therefore, accessing local temperatures, its spatial and temporal evolution together with their consequences is essential for FIB processing of sensitive materials with respect to chemical damage and morphological instabilities. In the first part we present an approach, which uses ion trajectory simulations as input data for a thermal spike model which allows the prediction of local temperatures and its lateral distribution during FIB processing (see Figure 1a). Taking into account the thermal behavior of polymers, combined simulations and calculations reveal very good agreement with FIB experiments on polymers (see Figure 1b) confirming the suitability of this combined approach to predict local temperatures and its spatial and timely evolution.

In second step we apply the gained knowledge together with an alternative patterning strategy for the preparation of TEM lamellas, which minimizes technically induced temperature effects [2]. By this careful adaption of the patterning strategy we will show morphological stabilization, characterized via scanning electron microscopy (SEM) and atomic force microscopy (AFM), and demonstrate the reduced chemical damage via IR-Raman spectroscopy. Based on these results, TEM investigations of polymeric layer systems and organic transistors will be shown which confirms stabilized morphologies and minimized chemical damage.

The study demonstrates the massive thermal stress a polymer is exposed during FIB processing and the capabilities of adapted FIB processing for low melting materials which can be easily implemented in most FIB systems. By that, new possibility for FIB processing capabilities for low melting materials open up which have been considered as very complicated or even impossible in the past.

1. J. Mayer, et al., MRS Bulletin 2007, 32, 5, 400 – 407

2. R.Schmied et al. RSC Adv., 2012, 2 (17), 6932 – 6938

The authors gratefully acknowledge the valuable support provided by Prof. Ferdinand Hofer, Prof. Gerald Kothleitner, Dr. Boril Chernev, and Martina Dienstleder. The authors also thank FFG Austria and the Federal Ministry of Economy, Family and Youth of Austria for their financial support.