IT-7-P-2095 In-situ Lorentz microscopy of high Bs and low core-loss Fe85Si2B8P4Cu1 nanocrystalline alloys

The Fe-Si-B-P-Cu nanocrystalline alloys which exhibit excellent magnetic softness and relative high saturation magnetic flux density have been newly developed. This material has a homogeneous nanocrystalline structure composed of alpha-Fe grains with a size of about less than 20 nm which are realized by crystallizing the heterogeneous amorphous alloys. In this study, we observed the movements of the magnetic domain walls in the heat-treated Fe85Si12B6P4Cu1 amorphous-ribbons by in-situ Lorentz microscopy using a transmission electron microscope equipped with a magnetizing system, in order to understand the dependence of the magnetic properties on the microstructures.

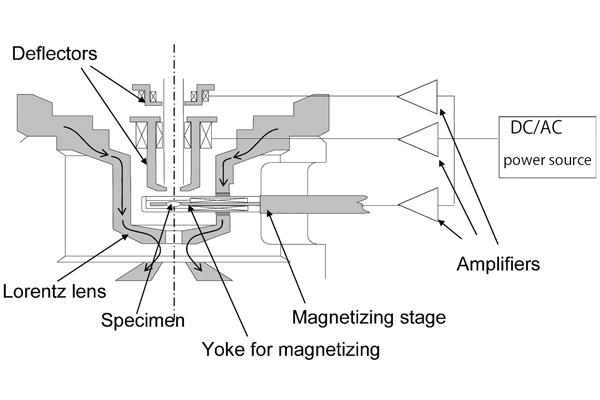

Figure 1 shows a schematic illustration of the magnetizing system installed on a JEM-3000F instrument. The magnetizing specimen holder and two deflection coils are connected to an electric power source via three independent amplifiers. The two deflectors control the incident angle of the electron beam to avoid shifting of the image on the screen. When the amplifiers are connected to the DC source, a static external magnetic field is applied to the specimen. In order to observe the motion of the magnetic domain wall, the amplifiers are connected to an AC source.

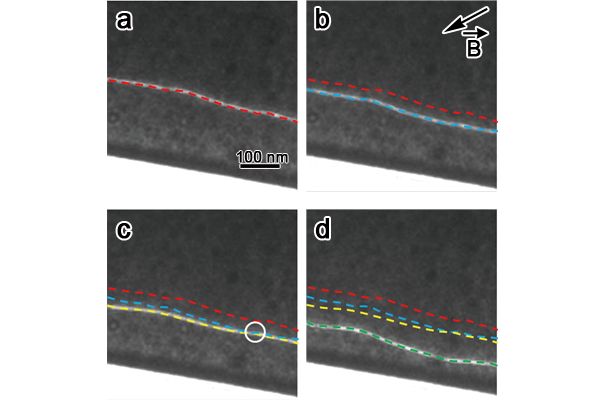

The smooth movement of magnetic domain walls was observed in the specimen which was heat-treated at 430 °C, while the specimen which was heat-treated at 470 °C showed less-smoothness of the domain wall motions. Both of two specimens have the nanocrystalline structure in which the size of alpha-Fe crystallite is about 5 nm, but the electron diffraction pattern indicates that the latter specimen contains precipitates of boride. Figures 2a to 2d show Lorentz micrographs of the specimen which was heat-treated at 470 °C in a static external magnetic field of 3.8 kA/m, 4.3 kA/m, 4.6 kA/m and 4.7 kA/m, respectively. The direction of the external magnetic field is indicated by arrow at the top right of the Fig. 2. The positions of the magnetic domain wall are indicated by a dotted line, and previous positions of the domain wall were also plotted on the images. It is noted that a pinning of the motion of domain wall was observed at the position indicated by a white circle in Fig. 2c. It was considered that the precipitates caused the less-smoothness of the domain wall motions.

This work was supported by "Tohoku Innovative Materials Technology Initiatives for Reconstruction (TIMT)" funded by MEXT and Reconstruction Agency, Japan.