IT-13-P-2068 Characterization of carbonaceous contamination and the cleaning capability of atomic hydrogen during focused ion beam processing

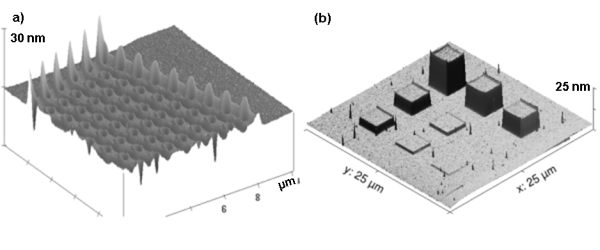

During focused ion beam (FIB) milling undesired peculiar depositions (Fig. 1a), from mainly carbon compounds of the residual gas at the edge of ion beam exposed regions, occur. Surface diffusion of residual gas molecules and the reduced ion dose are causing enhanced residual gas deposition rates at the boundary area of ion beam exposed regions [1]. Especially for sputtered structures with dimensions in the nanometer range, these unwanted ion beam induced depositions (IBID) can be of the same order of magnitude as the intended structures, therefore they must be eliminated.

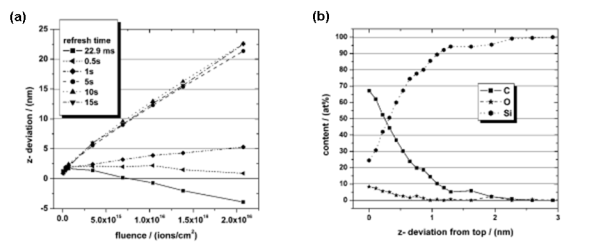

Preliminary, we have characterized the dynamics of this contamination growth. Crystalline (c-Si) and amorphous Si (a-Si) were irradiated by a 50 kV Ga+ ion beam, with various scanning parameters, under high vacuum conditions (2.7 × 10-7 mbar). A refresh time variation in several steps from 23 ms to 15 s was performed with a dwell time of 1 μs (Fig. 1b). Atomic force microscopy (AFM) measurements reveal that for refresh times longer than 1 s, IBID entirely inhibits the net volume loss by sputtering. The residual gas deposition rate saturates for a refresh time of about 5 s (Fig. 2a). Dwell time variations from 0.5 μs to 10 μs at a refresh time of 5 s show the expected decreasing in deposition rate. The pronounced indented shape of the deposits exhibits the influence of surface diffusion. A surface diffusion constant in the order of 10-9 cm2/s was roughly estimated. Auger electron spectroscopy (AES) depth profiles of the chemical composition of low dose ion irradiated c-Si show a mixture of Si, C, and O with decreasing C and O concentrations from top to the bottom of the deposits (Fig. 2b). The investigated depositions consist roughly of of 22 at% C and 2 at% O in addition to Si.

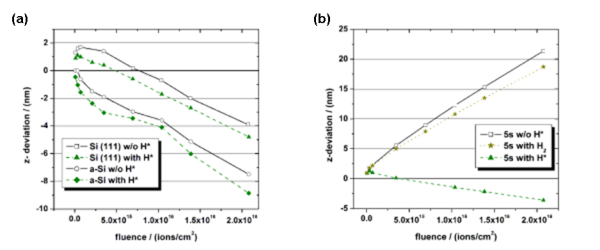

When an atomic hydrogen (H*) gas beam, generated by a thermal cracker source [2], has been delivered to a c-Si surface during FIB processing, reduced swelling heights in the range estimated from the difference in mass density of amorphous and crystalline Si were determined (Fig. 3a). Moreover, the H* delivery suppresses the residual gas deposition, even for refresh times in the range of seconds (Fig. 3b). We conclude that simultaneous Ga+ and H* bombardment removes adsorbed carbon compounds and the additional H* delivery impedes the surface diffusion of adsorbed residual gas molecules. Thus a significant build up of contamination can be avoided.

[1] J.B. Wang, A. Datta, Y.L. Wang; Applied Surface Science 135 (1998) 129-136

[2] K. G. Tschersich, J.P. Fleischhauer, H. Schuler; Journal of Applied Physics 104, 034908 (2008)

This work has been supported by the EC (FP6, CHARPAN, Contract no.: IP 15803-2).