IT-7-P-1941 Deformation modes of Au nanowires revealed by mechanical testing in TEM

Shrinking the size of metallic structures not only leads to an increase of strength (i.e. the ‘smaller is stronger’ size effect), but also to a change in the deformation mechanism. In the case of uniaxial deformation of face-centered cubic (fcc) metal nanowires, the deformation mechanism can also change with the loading condition. According to recent molecular dynamics (MD) simulations, ultra-thin Au [110] nanowires (diameters of a few nm) deform predominantly by dislocation slip in compression, but in tension by deformation twinning. Here we report, by combination of in-situ transmission electron microscopy (TEM) and molecular dynamic simulation, the conditions under which particular deformation modes take place during the uniaxial loading of [110]-oriented Au nanowires [1].

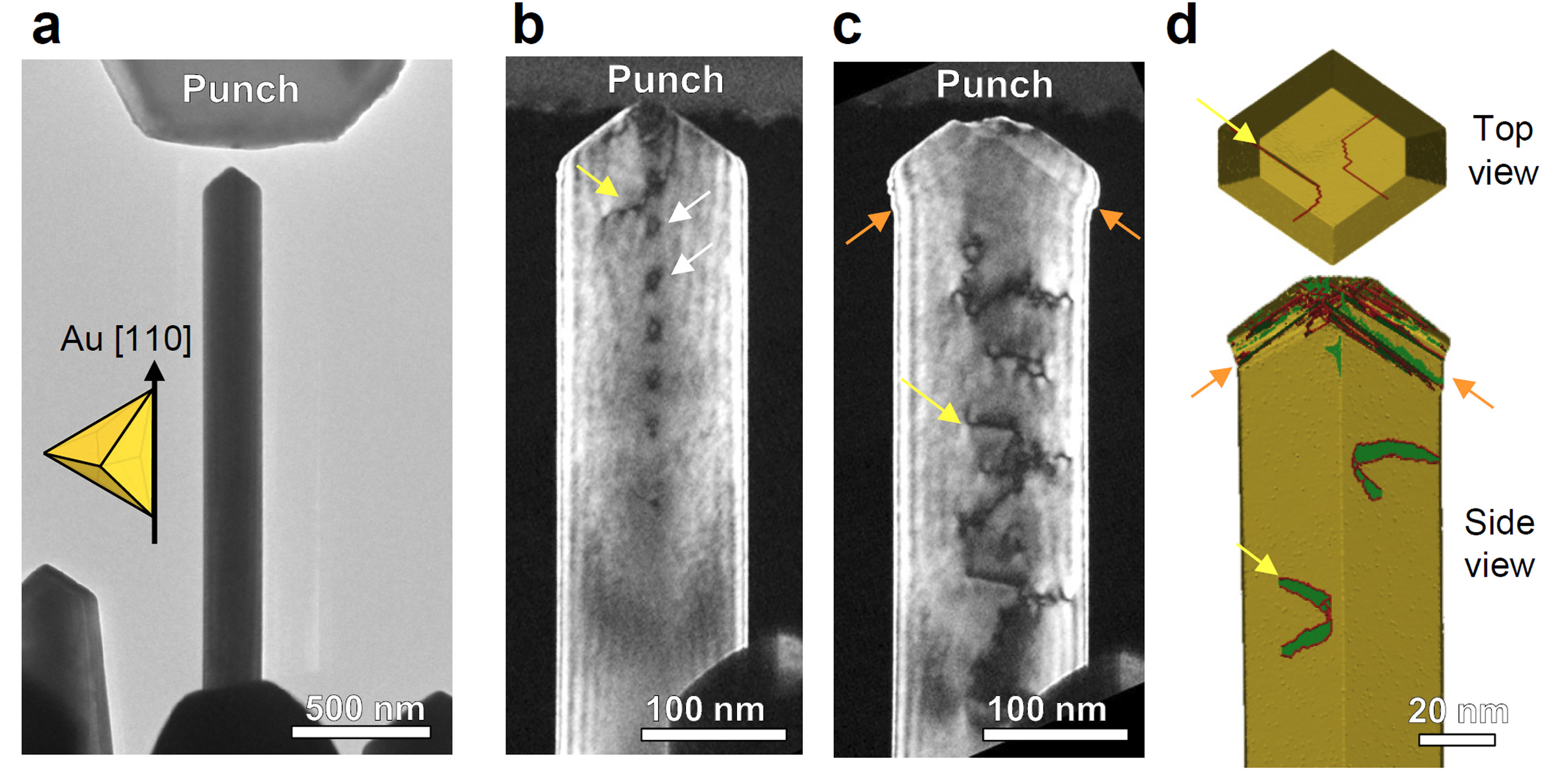

In our deformation setup in TEM, a wedge-shaped top end of Au [110] nanowire was first compressed with a flat diamond punch (Fig. 1a), thus the initial deformation was localized near the contact region. Under such a strain gradient condition, the initial compressive deformation began with the emission of small prismatic loops from the top corner (white arrows in Fig. 1b). Initially, the loops appeared to replicate the perimeter of the contact line, but after a certain number of closed loops were punched out (typically less than ten), there was a clear transition in the nucleation mechanism; open loop dislocations started to bulge out and then released from the contact area (yellow arrows in Fig. 1b-c). As the contact area increased, ordinary dislocation slip along the inclined {111} slip planes dominated the compressive deformation (Fig. 1c and d).

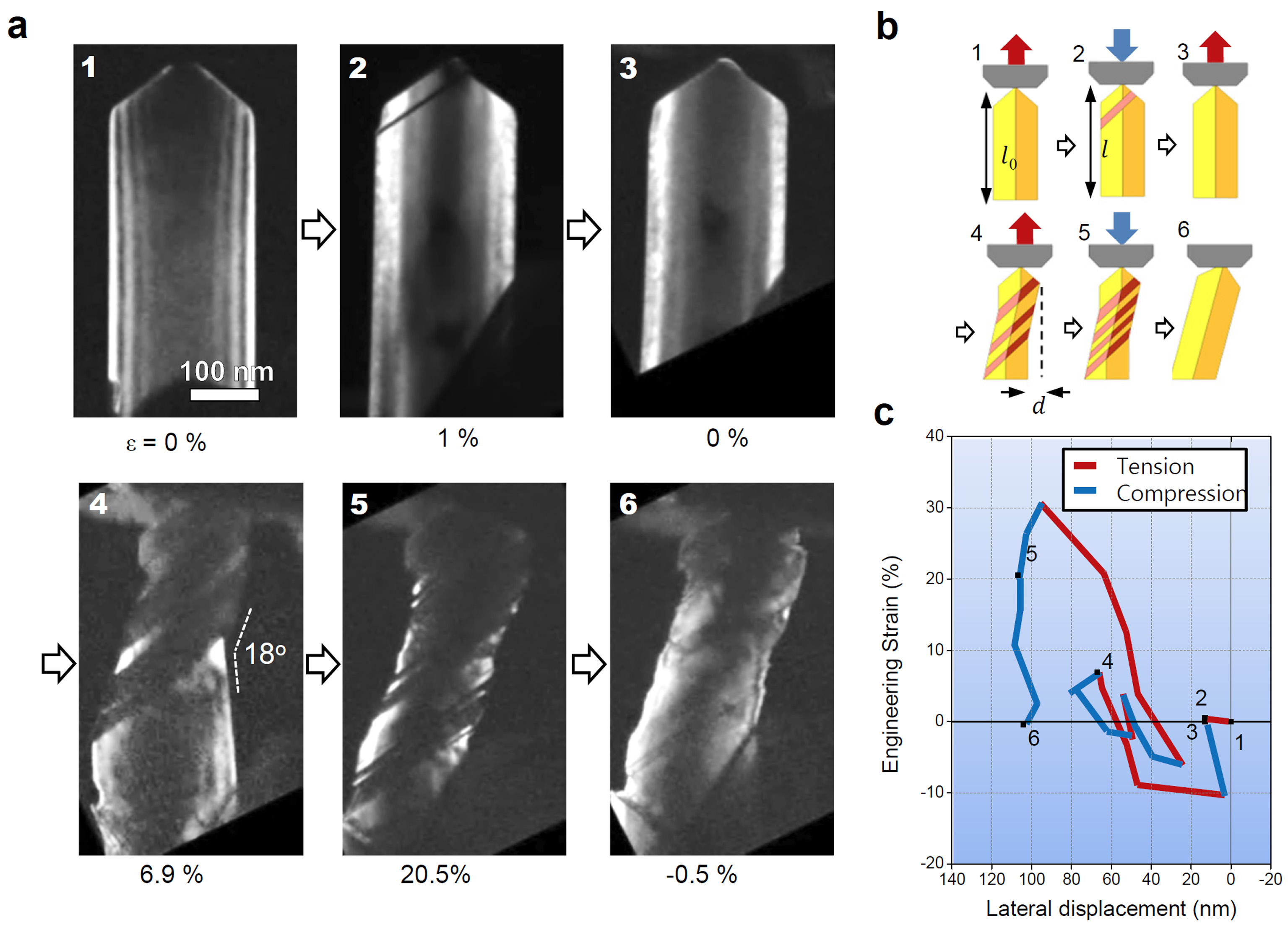

The deformation mode of Au [110] nanowires changes from dislocation slip to deformation twinning as the loading condition is reversed from compression to tension. Moreover, once a Au nanowire has been twinned by the initial tensile loading, the subsequent compressive deformation was carried predominantly by detwinning instead of the expected dislocation slip (Fig. 2a and b). This twinning-detwinning behavior is capable of accommodating large plastic strains (> 30%) reversibly and repeatedly over many tension-compression cycles (Fig. 2c). Molecular dynamics simulations rationalize the observed behaviors in terms of the orientation-dependent resolved shear stress, i.e. Schmid factor, on the leading and trailing partial dislocations, their potential nucleation sites and energy barriers. The present in-situ TEM results demonstrate the primary role of the loading direction in determining the governing deformation mechanisms under uniaxial loading conditions.

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (NRF-2011-0029406).