IT-7-P-1868 In situ mechanical testing in the transmission electron microscope and finite element method simulations on nanoscaled amorphous silica spheres – Densification, hardening and improved intrinsic properties on nanoscale

As functional members in electronic devices and fiber-based telecommunication techniques oxide glasses have become subject of intense research. In addition to functionality, oxide glasses often have to fulfil mechanical reliability. Because silica is relevant in electronic and optical applications, it is chosen as a suitable model system towards a general understanding of factors which control intrinsic strength, deformation and elastic properties of non-crystalline materials. Since glasses lack of long-range periodicity, usual strengthening strategies, which comprise introduction of defects or grain boundaries with the aim to inhibit dislocation motion [1], are not working. Hence, novel approaches are appreciated to improve their mechanical properties. In the past, electron beam (EB) irradiation was used to tailor the properties of materials [2], but facing the problem of increased specimen temperature. EB irradiation is also known to densify amorphous silica (a-SiO2) on macroscopic scale [3]. Recent in situ transmission electron microscopy (TEM) studies have shown that moderate EB irradiation is very useful to induce enormous ductility in nanoscale a-SiO2 [4].

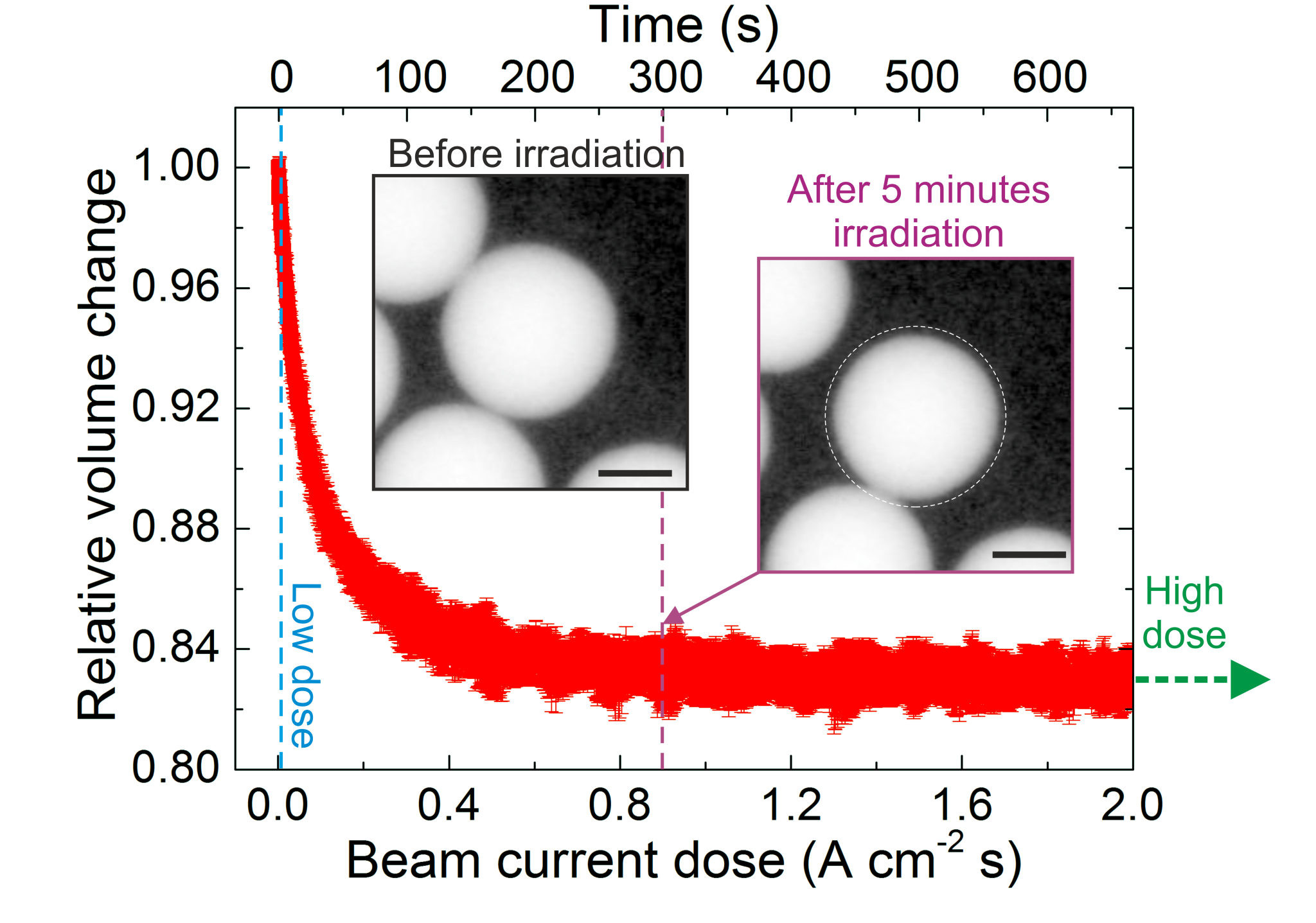

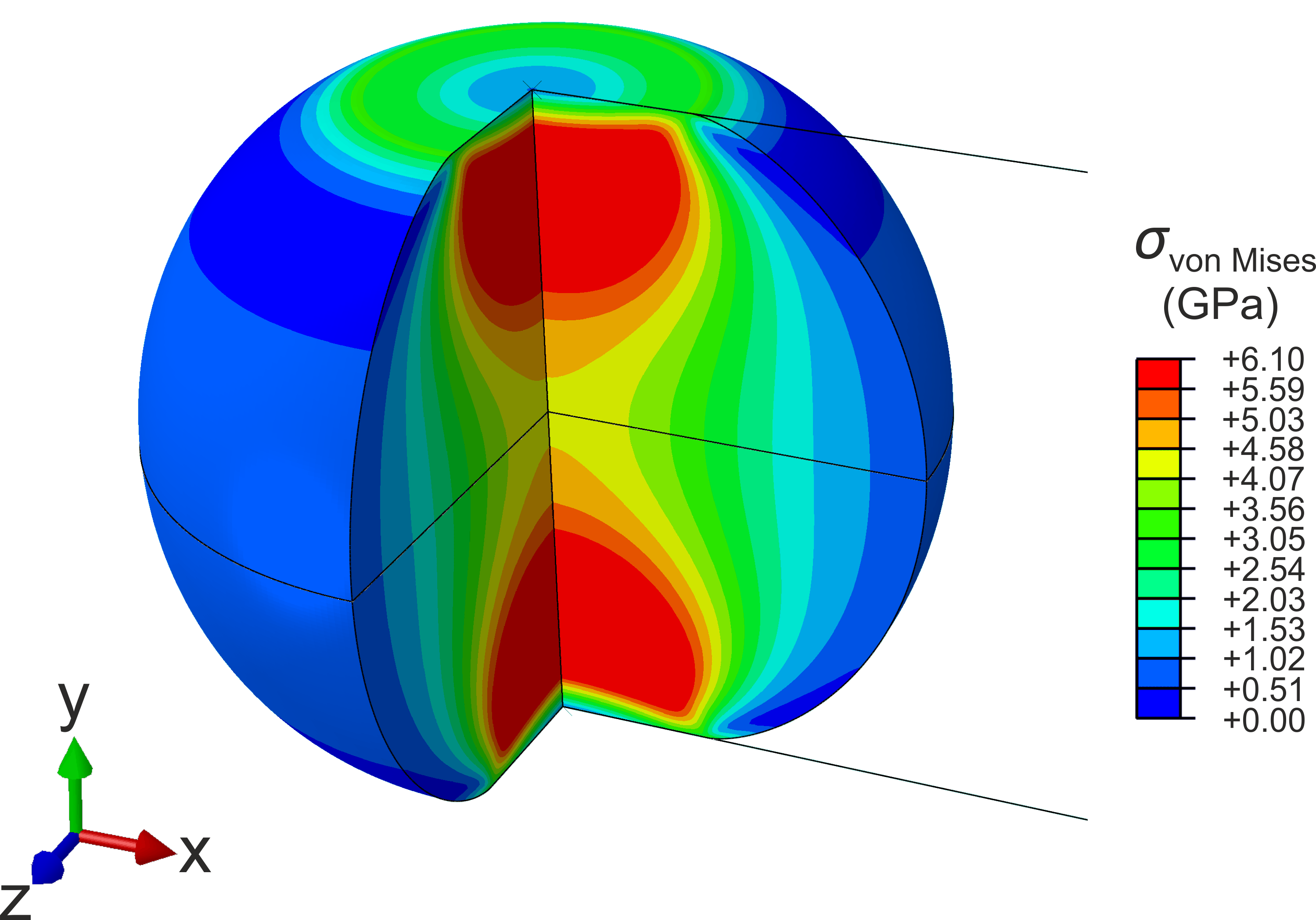

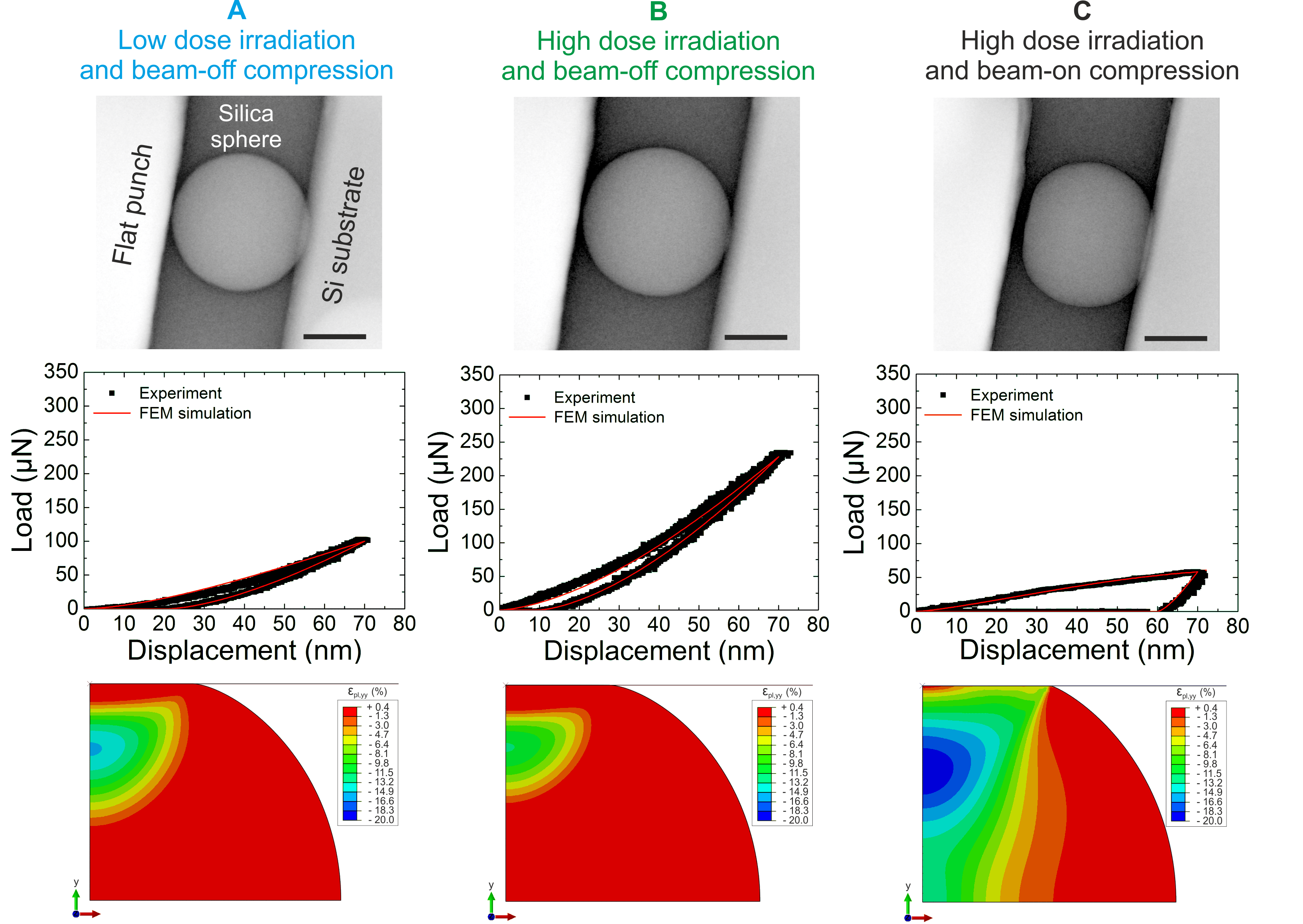

In the present study combined in situ mechanical testing in TEM and finite element method (FEM) simulations were used to characterize the mechanical properties of nanoscaled a-SiO2 spheres. First, the dose-dependent densification of a-SiO2 upon EB-irradiation was monitored in situ in TEM (Fig. 1). At low beam current doses (LD) a-SiO2 spheres densify clearly less compared to higher dose (HD) irradiation. In order to investigate the effect of EB irradiation on the mechanical properties, the spheres were irradiated with either LD or HD and then compressed under beam-off (Fig. 3a,b) or beam-on (Fig. 3c) conditions. We observe a pronounced hardening effect (Fig. 3), whereby higher loads are required to compress a-SiO2 spheres, which are treated with HD irradiation prior to compression [5,6]. FEM simulations based on an elastic / ideally plastic model (set-up in Fig. 2) reveal an increase in Young’s modulus upon HD irradiation (not shown) [6], as well as different plastic strains for beam-off and beam-on compression (Fig. 3). This clearly proves that the intrinsic glass properties can be tailored by EB irradiation [5]. Our approach is highly promising and opens opportunities for fundamental studies on structure-property relations of nanoscaled glass.

1. K. Lu et al., Science (2009) 324:349; 2. A. Krasheninnikov et al., Nature Mater. (2007) 6:723.

3. W. Primak et al., J. Appl. Phys. (1968) 39:5651.

4. K. Zheng et al., Nature Comm. (2010) DOI: 10.1038/ncomms1021

5. M. Mačković et al., Microscopy Congress MC2013, Regensburg, Proc. (Part 1), pp. 470-471.

6. M. Mačković et al., submitted.

Financial support by DFG via SPP1594 „Topological Engineering of Ultra-Strong Glasses” and the Cluster of Excellence (EXC 315) is acknowledged. The authors thank M. Hanisch and R.N. Klupp-Taylor for providing the amorphous silica spheres.