IT-5-O-1860 Nanocharacterisation of vanadium and niobium carbide and carbonitrides precipitates in austenite high manganese steels with DualEELS and HAADF techniques

In order to fulfil the twin goals of safety enhancement and reduced CO2 emissions combined with fuel efficiency for automotive applications, steels combining high strength and high ductility are required for structural members. One alloy system of interest for this application is high-manganese steel microalloyed with either Nb or V to provide high densities of nanoscale carbide or carbonitride precipitates to provide additional strengthening by the dispersion hardening mechanism. We report significant progress in the understanding of the atomic structure of such precipitates, together with their nanoscale chemistry using aberration-corrected analytical STEM. Specifically, we report the details of the precipitate morphology, and absolute measurements of the chemical composition, and use this to make plausible reconstructions of the 3D morphology of these few nm precipitates. This is achieved using DualEELS spectrum imaging datasets recorded with a Gatan GIF Quantum on a JEOL ARM 200F cold FEG, probe-corrected STEM at pixel spacing of a few Ångströms.

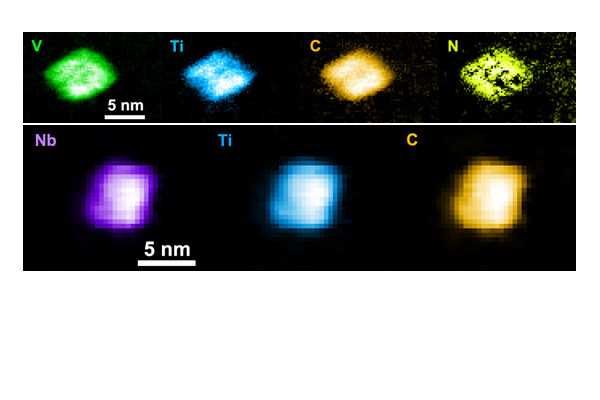

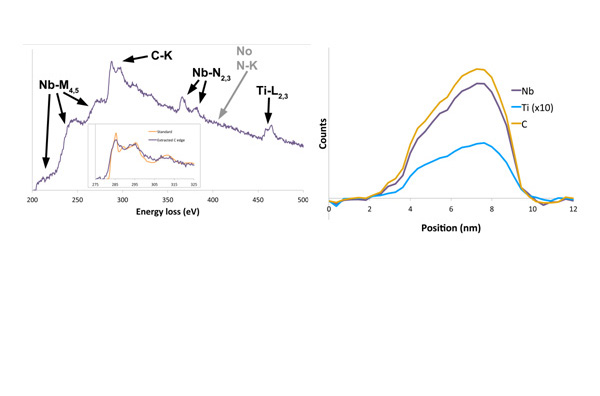

We show that a processing approach consisting of subtracting all artefacts from the dataset, followed by the subtraction of the matrix components from the dataset allows the creation of a spectrum image just representing the precipitate. This can then be quantitatively analysed both to produce an accurate thickness map using the t/λ method, and also to produce chemical maps of both the metal cation and carbon contents. Excellent correlation is found between all the maps showing that all elements are uniformly distributed throughout the precipitate, and it is shown that absolute thicknesses can be calculated using crystallographic parameters together with standards for the cross sections of Nb, V, C and Ti (present as impurities). It is shown that there is little evidence for any significant content of N in the precipitates, as is expected for an Al containing steel, and consequently we see little evidence of TiN nanoclusters acting as nucleation points for the precipitates. Rather, Ti impurities have exactly the same spatial distribution in the precipitates as the V or Nb. Nevertheless, we also show that in at least one case, a tiny concentration of N could be detected and mapped within a precipitate, which seems in this case to have been distributed across the whole precipitate.

We are grateful to the European Commission for the funding of this work as part of a Research Fund for Coal and Steel Project (Precipitation in High Manganese Steels, RFSR-CT-2010-00018). This work was only possible because of the generous provision of the MagTEM facility by SUPA and the University of Glasgow.