IT-14-O-1627 Using SPM nanomanipulation to discover new materials and properties

In this work, Scanning Probe Microscopy (SPM) was employed for matter manipulation at the nanoscale in ambient conditions. More specifically, the SPM nanomanipulation potential is illustrated by two recent works of our group: in the first one, a new material – diamondol – is proposed and its realization is evidenced via SPM experiments [1]. In the second one, the SPM nanomanipulation was used to both induce and discover a general property of solid lubricants: a negative dynamic compressibility [2].

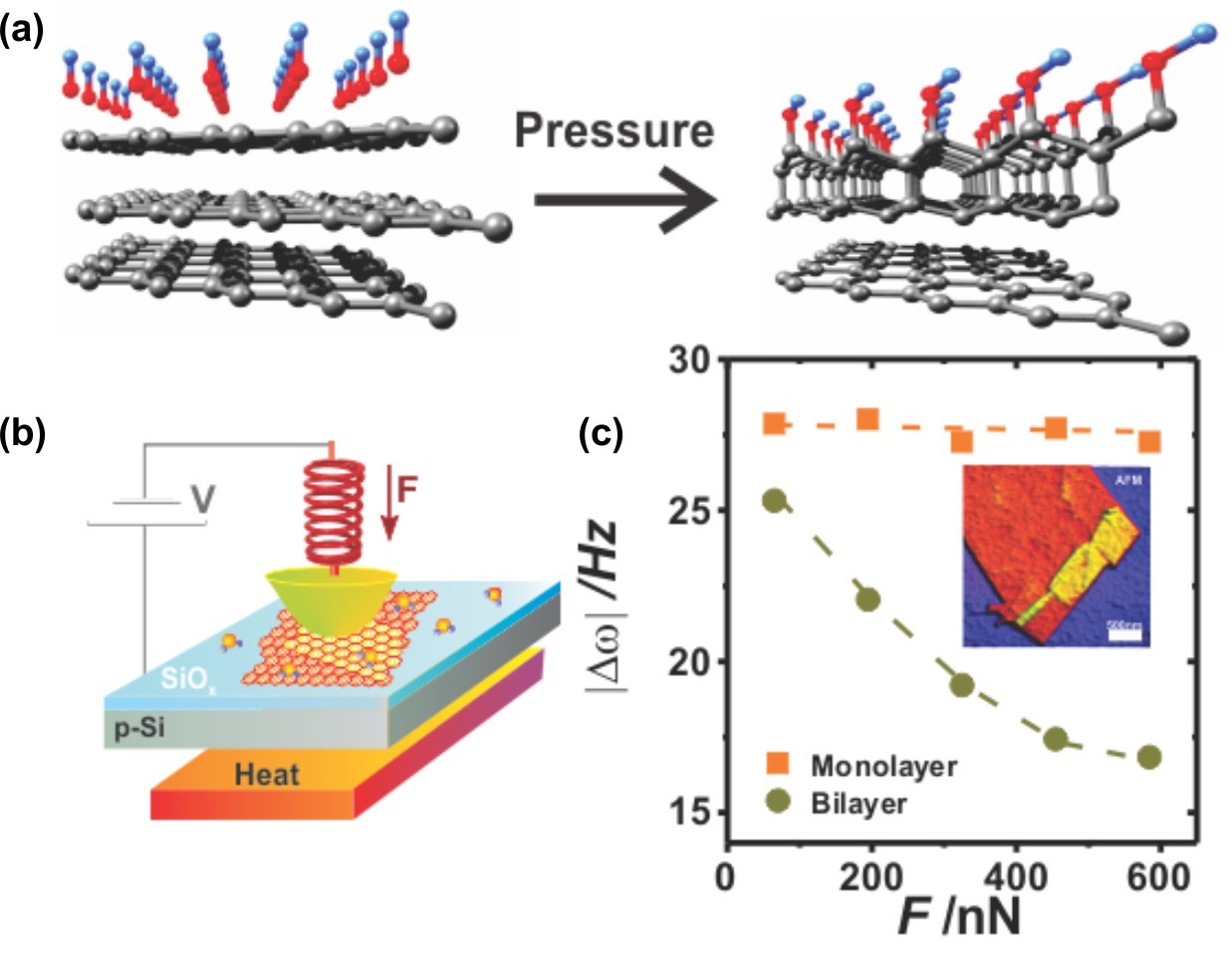

According to our ab initio calculations, the diamondol, or hydroxylated diamond, would be a new 2D material, formed via compression-induced diamondization of two, or more, graphene layers stabilized by hydroxyl ions (see Fig. 1a). The experimental observation of diamondol was carried out in a series of SPM experiments on mono-, bi-, and multilayer graphene in a controlled environment (humidity and temperature). Using electric force microscopy (EFM) to both inject and monitor charges and to apply pressure on the sample [3] (see Fig. 1b), we observed a pronounced inhibition on the charging efficiency for bilayer and multilayer flakes as the tip pressure increased, while monolayer charging was pressure-independent (Fig. 1c). The influence of the water content on the sample surface was tested in a series of charge injection experiments carried out at different temperatures (25°C and 120°C). The ensemble of experimental results can be well accounted for by the diamondol hypothesis, thus giving strong evidence of its experimental realization.

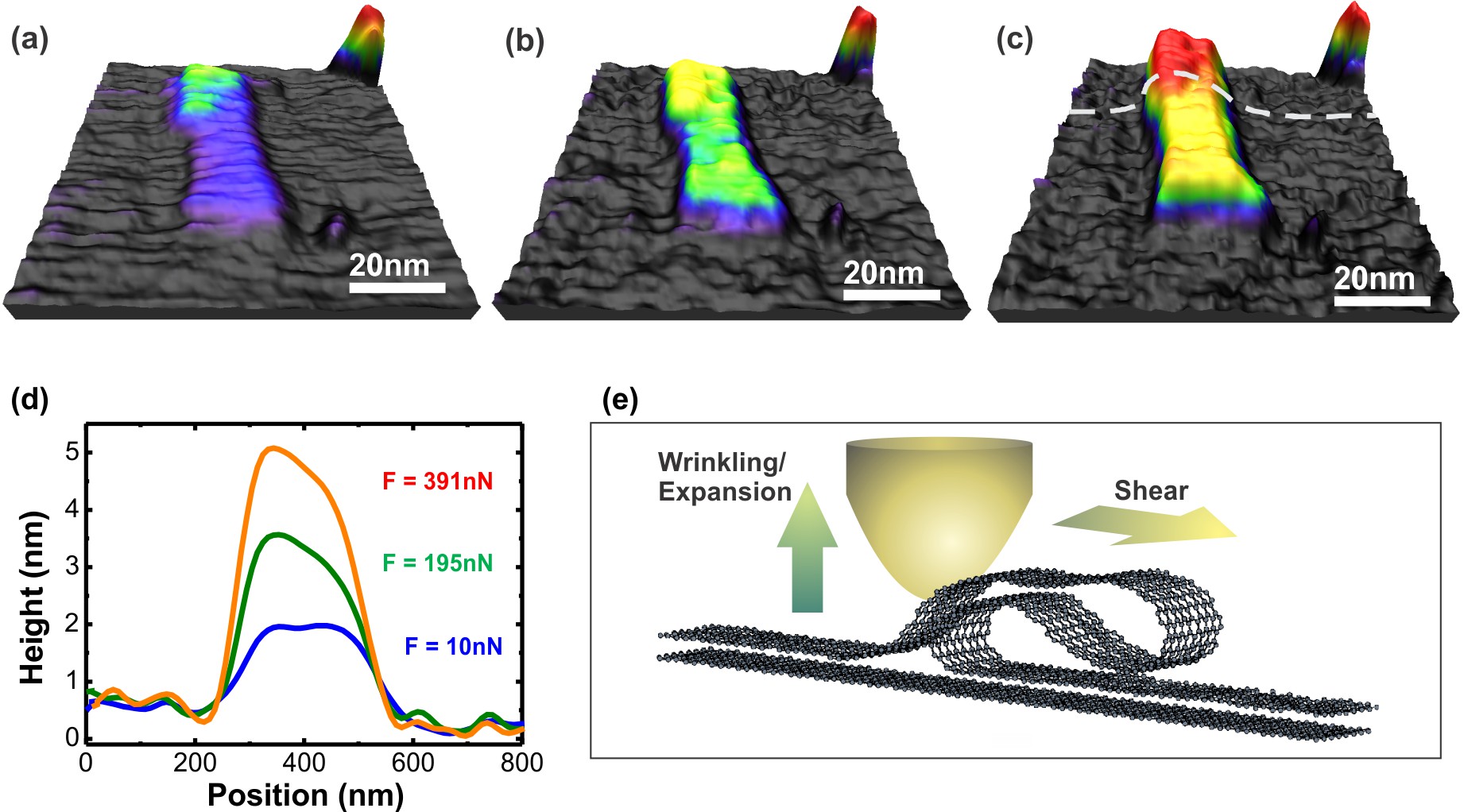

In the second study, a novel mechanical response of solid lubricants (few-layer graphene, h-BN, talc and MoS2) to the simultaneous compression and shear by a SPM tip is observed. The response is characterized by the vertical expansion of these 2D layered materials upon compression (see Figs. 2a-d). Such effect is proportional to the applied load, leading to vertical strain values (opposite to the applied force) of up to 150% (Fig. 2d). The effect is null in the absence of shear, increases with tip velocity, and is anisotropic. It also has similar magnitudes in these solid lubricant materials, but it is absent in single-layer graphene and in few-layer mica and Bi2Se3 (non-lubricant layered materials). We propose a physical mechanism for the effect where the combined compressive and shear stresses from the SPM tip induce dynamical wrinkling on the upper material layers, leading to the observed flake thickening (Fig. 2e). The new effect (and, therefore, the proposed wrinkling) is reversible in all four solid lubricants where it is observed.

Financial support from Fapemig, Capes, CNPq, Rede Nacional de Pesquisas em Nanotubos de Carbono, and INCT/Nano-Carbono is acknowledged.