IT-7-P-1582 Simultaneous in situ SEM/STEM observation of catalyst reaction under an air atmosphere using a Cold-FE environmental TEM

In the development of catalysts and fuel cell materials, there is an increasing demand for fine structural characterization using Environmental TEM (E-TEM). Recently, we have developed an E-TEM based on a conventional analytical TEM combined with a gas injection-specimen heating holder[1-2]. To further clarify the mechanism of the degradation of electrode-catalyst, a simultaneous in situ SEM/STEM study was carried out under the accelerated degradation condition. With the surface information from the SEM detector, we have obtained information in three-dimensional, gained significant new understanding of the behavior of Pt/C catalysts.

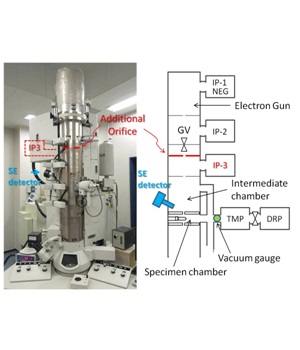

Figure 1 shows an overview and a schematic diagram of the specially designed Hitachi HF-3300 Cold-FE in situ TEM equipped with STEM and SEM imaging capabilities. In order to maintain the electron gun area under ultrahigh vacuum of better than 10-8 Pa near the gun, yet introducing gas into the specimen chamber, an additional ion pump (IP3) and an extra orifice have been added between the gun valve and specimen chamber. In situ simultaneous SEM/STEM observation in a gaseous atmosphere is realized by using the gas injection specimen heating holder.

A picture and a schematic diagram of the gas injection specimen heating holder are shown in Figure 2(a) and 2(b), respectively. The reaction gas is introduced to the area around the specimen by means of a gas injection nozzle. Therefore, in situ observation in a gaseous atmosphere can be carried out using this Cold-FE TEM even if up to 10 Pa near the specimen. The specimen was used a commercially available Pt/C catalyst. To simulate an accelerated aging, the specimen was heated to 200˚C. The morphological changes of Pt/C catalyst operated at accelerating voltage of 300 kV.

Figure 3 shows the results of in situ SEM/STEM simultaneous observation. At the beginning of air with a measured specimen chamber pressure of 1 Pa after 270 sec., a cluster of Pt particles on the carbon support have grown and agglomerated, and the number of Pt particles appeared to decrease on the carbon support, as indicated in red circle. After 660 sec., most of the Pt particles have gradually started inserting into the carbon support, and the grain growth and agglomeration of Pt particles have occurred inside the carbon support, as shown in Figure 3. After 1080 sec., the behaviors of migration, coalescence and grain growth of Pt particles inside the carbon support were clearly observed by STEM image.

References

[1] T. Yaguchi et al., J. Electron Microsc., 61(4), 199-206 (2012)

[2] T. Kamino et al., J. Electron Microsc., 54(6), 497-503 (2005)

The authors gratefully acknowledge Professor Kazunari Sasaki and Associate Professor Akari Hayashi of Kyushu University for valuable discussions.