IT-6-P-1552 In situ and related TEM techniques for the characterization of chemically synthesized nanomaterials

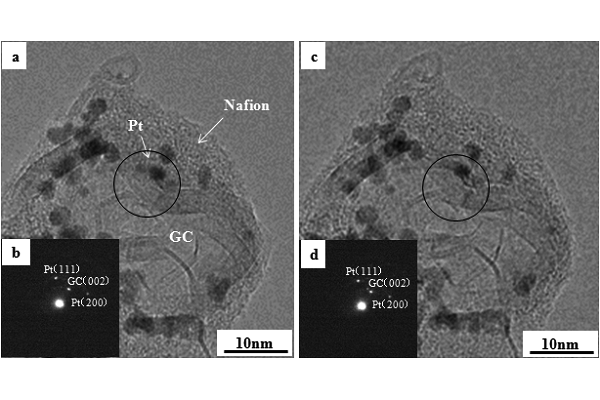

The wide range of techniques associated with an environmental transmission electron microscope (ETEM) are now applied to the studies of the nanomaterials used in the batteries and fuel cells. We have developed a specimen heating holder for in situ TEM observation of gas-solid reaction at elevated temperatures. The specimen heating holder has a nozzle for gas injection adjacent to the specimen. This unique design of the holder, together with the differential pumping system of the TEM, has made it possible to achieve a maximum gas pressure of about 100 Pa, at the specimen area, without affecting the vacuum of the electron gun chamber. The short gas path length, of only 50 cm, from a gas bottle to the nozzle, enabled us to replace the gas atmosphere in the specimen area, within several seconds. In recent years, the technique has been applied to the characterization of the degradation mechanism of the electrocatalysts of polymer electrolyte fuel cells as reported elsewhere. Most of the chemically synthesized metal-matrix nanoparticles contain organic elements as a residue, and if electron irradiation exceeds critical levels, the residue may be sputtered out from the particle, and the particle may crystallized. Therefore, careful control of illumination conditions and irradiation time are essential for the analysis of those materials. The results of our recent study revealed that the classic selected area diffraction (SAD) is one of the preferable techniques in the structural analysis of the composite. Figure 1 shows TEM images and SAD pattern of a Nafion coated Pt/GC electrocatalyst observed at 200kV with

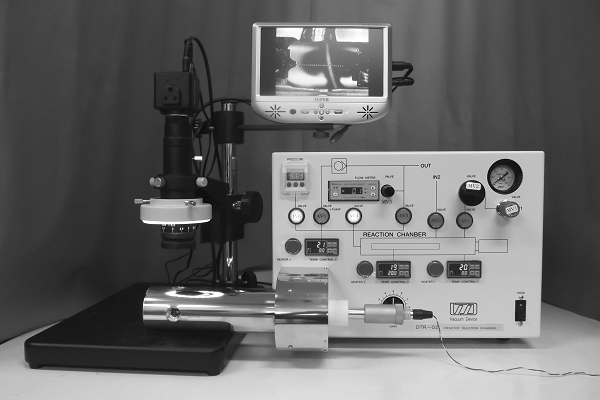

the electron beam density of 25 mA/cm2 on the specimen. Except for a slight deformation of the GC layer, the morphology of the specimen remained unchanged during the electron beam irradiation, for 14 minutes. The microscope used for the observation was a Hitachi H-9500 environmental TEM equipped with a standard high resolution objective lens pole-piece. The size of the field limiting aperture, used for the SAD pattern observation, was 1.0 micrometer and the size of the selected area was smaller than 15nm. The result reveals that an intermediate voltage TEM can be applied to the study of beam sensitive composites if the observation condition is carefully controlled. However, the influence of the electron beam, in the phenomena observed, in situ, can not be completely avoided. From this point of view, we have developed a gas reaction device for ex situ TEM study ( Fig.2 ) . The chamber is designed for use with the TEM specimen heating holders so that comparison of the results of in situ experiments, with that of an ex situ experiments, or a combination of both experimental techniques, using same specimen heating holder, are possible.