IT-11-P-1545 A thin film Zernike phase plate micro fabricated using MEMS technology.

An image of biological and polymer samples with conventional transmission electron microscopy (TEM) shows relatively low contrast without staining because they are composed of light elements such as carbon, nitrogen and oxygen. Zernike phase contrast TEM (ZPC-TEM) is an answer to this problem [1]. So far, many types of phase plates (i.e., thin film, electrostatic, magnetic, etc.) for TEM have been proposed [2]. Above all, a thin film phase plate has produced promising results [3]. Accordingly, ZPC-TEM attracts increasing attention to Cryo-TEM applications such as cryo-electron tomography and single-particle analysis, since a specimen in the field of interest is composed of light elements and preferred to be unstained to avoid artifacts.

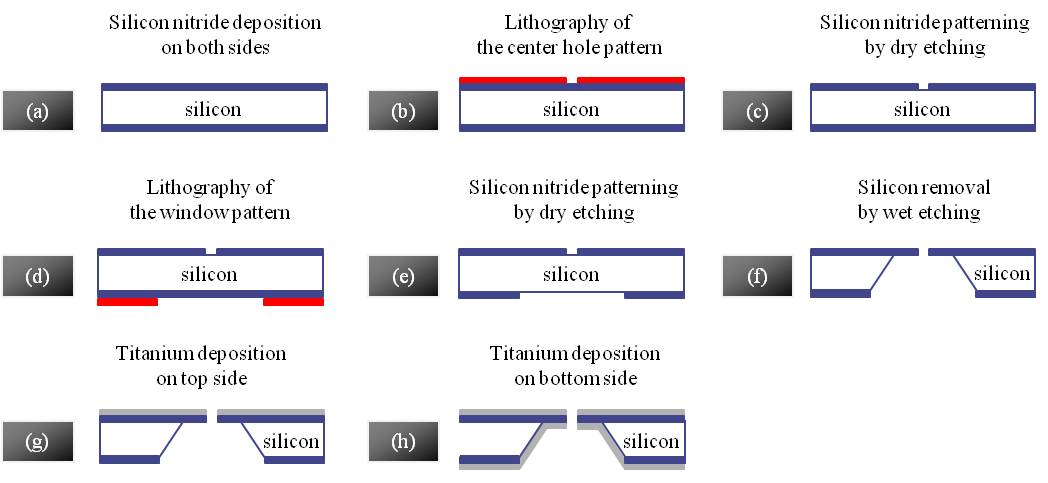

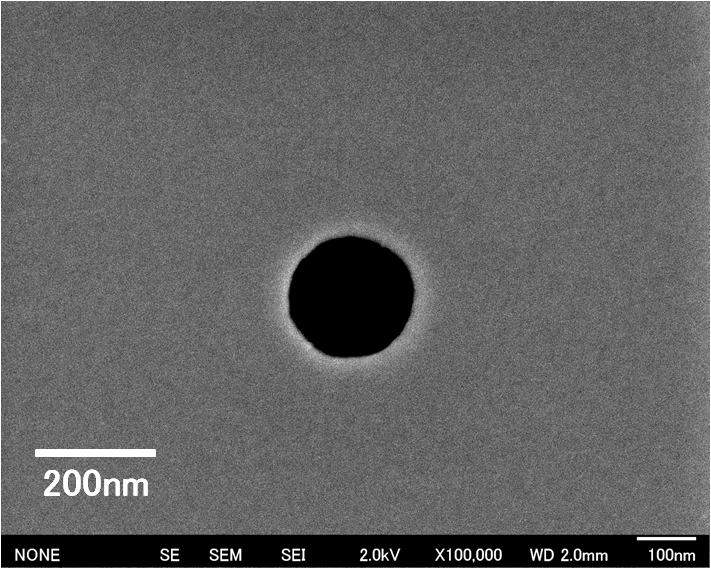

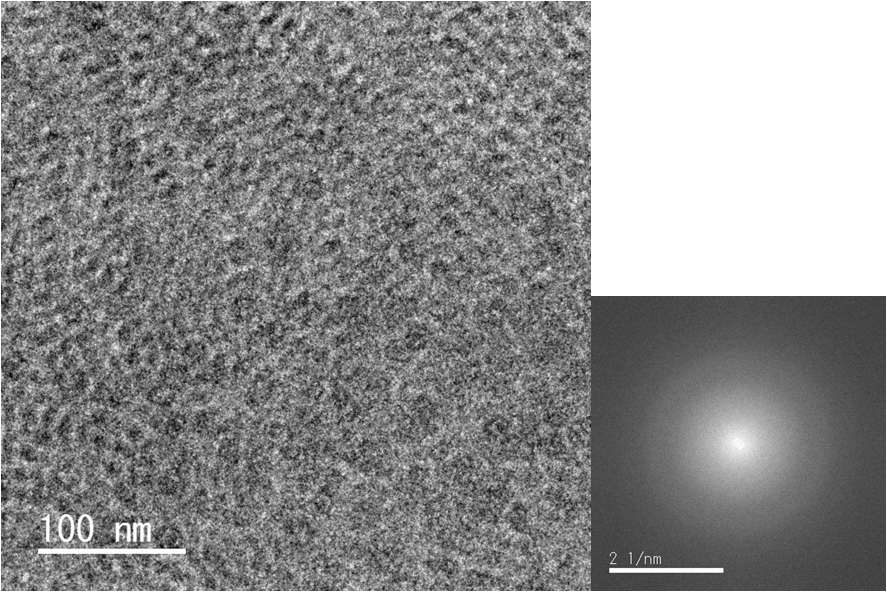

The thin film phase plate has however encountered a few problems. The most crucial one is charging that makes its reliability poor and its lifetime short. The second problem is that the fabrication of the phase plate has been made by human hands. For these problems we have tried to produce a phase plate through a mass production process of micro fabrication using micro electro mechanical system (MEMS) technology. At the first onset, we made a sandwich plate composed of silicon nitride (SiN) coated with metallic titanium (Ti) on both sides to reduce the charging. The entire process is shown in Fig.1. In the process the center hole, which is the most essential part for phase plate performance, was also produced by electron beam lithography and dry etching process. By virtue of these processes, the center hole is close to a perfect circle as shown in Fig. 2. And constant hole diameters in the mass-produced phase plates were assured. The left part of Fig. 3 shows a ZPC-TEM image of carbon thin film (Quantifoil) obtained with a Ti/SiN/Ti thin film phase plate using a field emission TEM (JEM-2200FS) and the right part shows its Fourier transform. According to the Fourier transform, we confirmed that the contrast increases in a low spatial frequency region.

Reference

[1] Danev, R. and Nagayama, K., Ultramicroscopy 88, 4, 243 (2001).

[2] Glaeser, M, Rev. Sci. Instrum. 84, 111101 (2013).

[3] Dai, W. et al, Nature, 502, 707 (2013).